Are you trying to decide between sublimation vs screen printing for your next project? Both methods offer unique benefits, but understanding the differences can help you choose the right process. From vibrant photo-quality prints to bold, solid colors, here’s what you need to know to make the right choice.

What Is Sublimation Printing?

Are you looking for a way to create vibrant, long-lasting prints? Sublimation printing could be the ideal choice for you. I will give you a look at what sublimation printing is and how the process works to help you decide if it’s the right fit for your products.

Definition

Sublimation printing is a process that uses heat to transfer dye onto materials. What sets it apart from other printing methods is that the ink actually becomes part of the material itself.

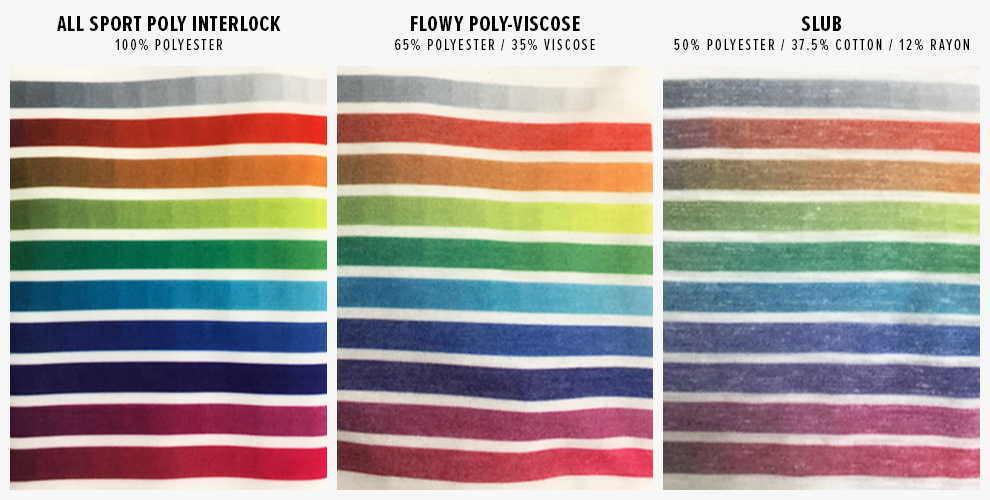

Rather than sitting on the surface, the dye infuses directly into the fabric, resulting in a smooth, vibrant print that looks and feels like it’s part of the fabric. Sublimation printing works particularly well on polyester fabrics and coated surfaces, making it perfect for apparel, mugs, phone cases, and even promotional items like keychains.

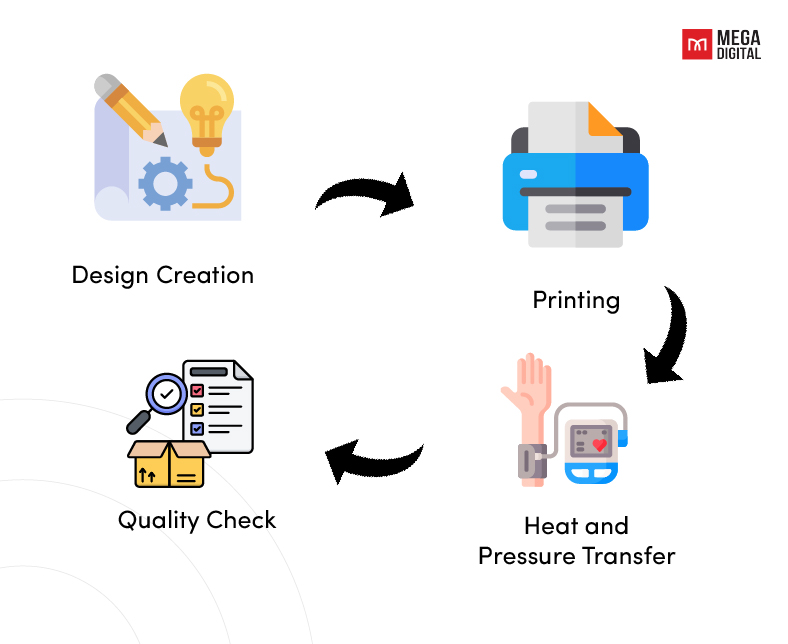

How Does Sublimation Printing Work?

The magic of sublimation lies in its scientific approach to transferring ink. Here’s a breakdown of the process:

- Design Creation: Use design software like Adobe Illustrator or Photoshop to create your artwork, ensuring it’s mirrored for proper transfer.

- Printing: Print your design onto sublimation paper using a dye-sublimation printer set to 300 DPI or higher to capture fine details.

- Heat Transfer: Position the design on your item, secure it with heat-resistant tape, and press at 380-400°F for 30-60 seconds to transfer the ink onto the material.

- Quality Check: Remove the paper and carefully inspect the print for any imperfections, adjusting heat settings as necessary to achieve a vibrant, lasting finish.

What Is Screen Printing?

If you’re looking for an old but gold technique that produces bold, durable designs, screen printing might be just what you need.

Definition

Screen printing, also known as silkscreen or serigraphy, involves using a mesh stencil to transfer ink onto a surface. Each color in the design requires a separate screen, making it a highly customizable but somewhat labor-intensive process. This layering of inks results in vibrant, opaque colors, which are especially effective on darker fabrics.

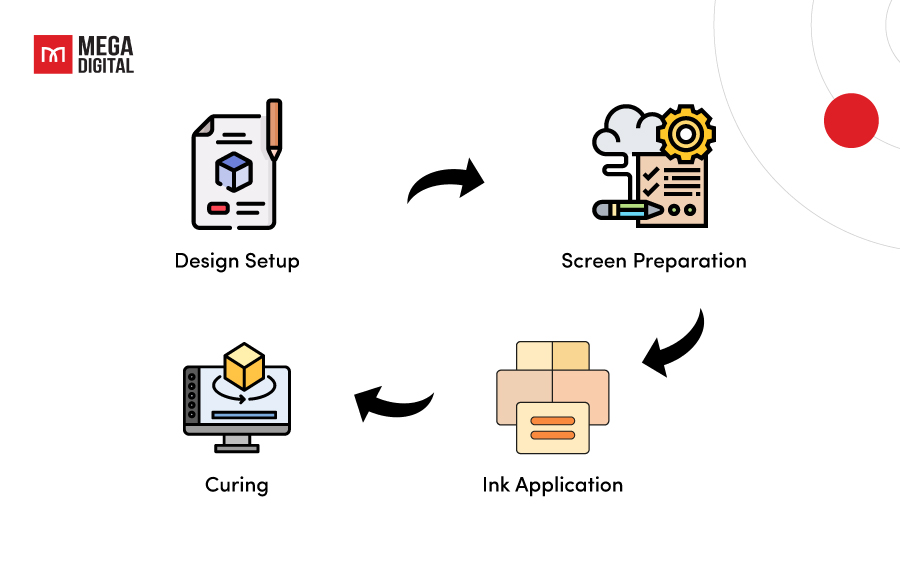

How Does Screen Printing Work?

Here’s a quick look at the screen printing process:

- Design Setup: First, a design is separated by color, and individual stencils (screens) are created for each layer of the design.

- Screen Preparation: A fine mesh screen is coated with a light-sensitive emulsion and then exposed to light with the design overlaid on it. This exposure hardens the emulsion except where the design blocks it, creating an open area for the ink to pass through.

- Ink Application: The prepared screen is placed over the fabric, and ink is pushed through the open areas of the stencil using a squeegee. For designs with multiple colors, each screen is aligned precisely to create the final image.

- Curing: After printing, the fabric is heated to cure the ink, making it durable and resistant to fading.

Sublimation vs. Screen Printing: 8 Key Differences

If you are a seller working in the POD, it’s essential to understand how each process impacts the final product. Now I will give you a detailed breakdown to help you decide which is best for your needs.

#1 Print Quality

First off all, let’s compare sublimation and screen printing quality based on image detail, texture, and finish to help you decide which one suits your needs.

| Aspect | Sublimation Printing | Screen Printing |

|---|---|---|

| Image Detail | High-definition, photo-quality results | Sharp lines but best for simpler designs |

| Texture | Smooth, as the ink fuses with the material | Slightly textured feel due to layered ink |

| Finish | Embedded within the material | Sits on top of the fabric |

Conclusion: If you want intricate, photographic designs, sublimation is your go-to. For bold, simple graphics, screen printing offers a reliable, vibrant option.

>>> Read more: What is DTG Printing? A Comprehensive Guide for Beginners

#2 Print Complexity

Here’s a comparison table for Print Complexity in sublimation and screen printing:

| Aspect | Sublimation Printing | Screen Printing |

|---|---|---|

| Complexity Handling | Easily handles complex, multi-color designs without added steps or costs | Challenging for complex designs; each color needs a separate screen |

| Color Blending | Excellent for gradients and subtle color transitions | Limited; best for bold, solid colors without blending |

| Fine Detail | High precision for small details and intricate artwork | Works well for simpler shapes but loses detail with fine lines |

| Setup Process | Minimal setup; digital process transfers directly to material | Lengthy setup; requires stencils for each color |

Conclusion

If you need a design that blends colors or includes small details, sublimation is the clear winner. However, for designs with large blocks of solid color, screen printing will give you bold, consistent coverage.

#3 Color Blending

When it comes to complex designs, achieving smooth transitions between colors can make or break the final look. Let’s explore how each method handles color blending and which one best fits your design vision.

Sublimation Printing

Sublimation printing allows for smooth, seamless color blending, making it perfect for designs with gradients, shading, or photo-quality images. Because the dye bonds directly with polyester fibers, colors appear deeply integrated, resulting in vivid transitions without sharp lines.

Recommended color uses for sublimation printing:

- Gradient Designs: Smooth color transitions, like sunset hues, work beautifully on polyester, creating a lifelike effect.

- Photo-Quality Prints: Sublimation is ideal for photographic images with complex shading and detail.

- Bright, Multi-Colored Designs: Designs with lots of colors, like floral patterns, look vibrant and sharp on synthetic fabrics.

Screen Printing

Screen printing is best for solid, bold colors, as each shade is applied in individual layers. This makes it more suitable for simple, high-contrast designs rather than detailed gradients or blends. If you’re aiming for a strong impact with distinct colors, screen printing is an excellent choice.

Recommended color uses for screen printing:

- Bold, Solid Colors: Primary colors like red, blue, and green are highly effective for logos or text.

- High-Contrast Designs: Screen printing creates a striking effect with two-tone designs, especially black-and-white.

- Simplified Gradient Effects: For a subtle gradient, consider using halftones to create a blended effect with screen printing.

Conclusion

You can choose sublimation for smooth color transitions and detailed images on synthetic fabrics. On the other hand, for bold, simple graphics on natural fabrics, screen printing is ideal.

>>> Read more: What Is Print on Demand? Pros, Cons, and How to Get Started

#4 Special Effects

Adding special effects to your prints can elevate a simple design, giving it extra flair and making it truly stand out. Let’s take a look at how sublimation and screen printing each perform with special effects and help you decide which one suits your creative vision.

Sublimation Printing

Sublimation has a flat, matte finish with no special effect options. Since the ink becomes part of the fabric, it doesn’t allow for metallic or 3D effects. Sublimation works well for high-definition images that require vibrant colors without texture, like custom designs on apparel or hard surfaces like metal or ceramics.

Recommendations for Sublimation Printing:

- Use sublimation when you need a flat, smooth finish with high image quality, such as on polyester shirts or hard surfaces like mugs.

- Avoid sublimation if you need special effects like metallic, gloss, or puff finishes, as these are not compatible with this method.

Screen Printing

Screen printing allows for a wide variety of effects, including metallic, gloss, and puff (3D) inks. These options create a tactile experience and add visual interest, making screen printing a favorite for promotional items or apparel that need extra flair. Metallic inks add shimmer, while puff inks create a raised, 3D effect that enhances the design’s visibility.

Recommendations for Screen Printing:

- Choose screen printing if your design would benefit from metallic or glossy finishes on apparel or accessories.

- Use screen printing with puff or textured inks for a raised effect, which works well on sweatshirts or promotional items.

- Avoid screen printing for highly detailed images where flat color is essential, as the effects can obscure fine details.

Conclusion

If you want special effects like metallic or puff finishes, screen printing provides these options. For flat, high-quality images with no additional texture, sublimation printing is the better fit.

#5 Fabrics and Materials

The type of fabric or material you choose plays a crucial role in the printing process and impacts the quality, durability, and appearance of the final product. Below I will explain what each technique offers for different types of fabrics and surfaces.

Sublimation Printing

Sublimation printing works only on polyester fabrics or specially coated items. It’s not effective on cotton or natural fibers, as the dye requires a synthetic surface to bind. This makes it ideal for sportswear, outdoor gear, and promotional items like mugs or phone cases designed for high durability and color vibrancy.

Recommendations for Sublimation Printing:

- Choose sublimation for polyester fabrics or synthetic materials where vibrant, long-lasting color is needed.

- Use sublimation for hard goods with a sublimation coating, like mugs, phone cases, and metal plates.

- Avoid sublimation on cotton or uncoated materials, as the dye will not bond effectively.

Screen Printing

Screen printing is highly versatile and compatible with natural fibers like cotton, as well as synthetics. It allows for printing on various surfaces, from apparel to accessories and banners. This method is ideal for bulk orders of cotton items, as it provides reliable, long-lasting prints with high-quality color retention.

Recommendations for Screen Printing:

- Opt for screen printing on cotton t-shirts, hoodies, and tote bags, especially for large batch production.

- Use screen printing for multi-material products, as it’s compatible with fabrics, wood, and even some plastics.

- Avoid screen printing on small, intricate designs with numerous colors, as each color adds to production complexity.

Conclusion

Sublimation is the preferred choice for polyester and coated items, while screen printing is ideal for cotton and a variety of materials, making it versatile for bulk orders and diverse products.

#6 Durability

Durability is a key consideration when deciding on a printing method, especially if your products will undergo frequent wear or washing. Let’s compare how sublimation and screen printing stack up in terms of fade resistance and wear over time.

| Aspect | Sublimation Printing | Screen Printing |

|---|---|---|

| Fade Resistance | High fade resistance, especially on polyester | Generally durable, though colors may fade over time |

| Wear Over Time | Very durable; designs resist peeling and cracking | May crack or peel, especially on well-worn items |

Conclusion: Sublimation is the winner for long-lasting prints on synthetic materials, while screen printing holds up well but may show wear with heavy use.

#7 Environmental Friendliness

Now, let’s break down how sublimation and screen printing compare in terms of sustainability.

| Aspect | Sublimation Printing | Screen Printing |

|---|---|---|

| Waste | Minimal waste; no excess materials used | Moderate waste; requires stencil cleaning and excess ink |

| Chemical Usage | Fewer chemicals, especially with eco-friendly inks | More chemicals are needed for stencil cleaning and ink removal |

| Energy Consumption | Moderate; uses heat press, which requires energy | Higher; uses dryers and exposure units for screens |

| Sustainable Inks | Easily compatible with eco-friendly, water-based inks | Can use eco-friendly inks, but not as widely available |

| Recycling Options | Limited recycling due to the type of materials used | Screens can be reused, but ink waste still remains |

Conclusion

Sublimation printing is more environmentally friendly, with lower waste and fewer chemicals. While screen printing can use eco-friendly inks, it generally generates more waste and requires more energy. If sustainability is a key factor for your business, sublimation is the better choice.

#8 Costs

Here’s a cost comparison table for sublimation vs. screen printing, based on factors such as setup costs, per-unit costs, and suitability for different order sizes:

| Aspect | Sublimation Printing | Screen Printing |

|---|---|---|

| Equipment Cost | $300 – $2,000 for a sublimation printer (mid-range models) | $1,500 – $10,000 for screen printing press, depending on size |

| Heat Press Cost | $200 – $1,500 (required for sublimation) | Optional but useful, around $300 – $1,500 |

| Ink and Consumables | $0.50 – $1 per print (sublimation inks, paper) | $0.10 – $0.25 per color, per print (screen printing inks) |

| Screen Making Supplies | Not needed | $20 – $50 per screen (includes mesh, emulsion, and cleaning) |

| Maintenance Costs | Minimal, around $50 – $100/year | Moderate, around $200 – $500/year for equipment maintenance |

| Overall Operational Costs (Monthly) | Estimated $100 – $300, depending on production volume | Estimated $400 – $700, depending on production volume |

Conclusion

- Sublimation: Great for smaller batches or unique, custom designs, with stable costs and minimal setup. Suitable for orders under 50 units, with per-item costs around $3 – $5.

- Screen Printing: Ideal for bulk orders over 50 units, especially for simple or fewer-color designs. The initial setup costs are offset with larger volumes, and per-unit costs can drop to as low as $1.50 for bulk runs.

Sublimation vs Screen Printing: Which Method is Right for Your Products

Now that you know what sublimation and screen printing can accomplish, let’s dive deeper into what each method can achieve and how to decide which one aligns best with your goals.

What Can You Do With Sublimation Printing?

Sublimation printing is ideal for vibrant, full-color designs, especially on polyester materials or coated surfaces. Here’s what makes sublimation unique:

- Photo-quality results: Sublimation is perfect for intricate, photo-quality designs. If you’re looking to print vibrant images with fine details, like a company logo or a scenic photograph, sublimation handles it with ease.

- Durability: Sublimated designs bond directly to the product, creating a print that resists fading and wear. This makes it especially useful for items that will be exposed to heavy use or regular washing, like drinkware, phone cases, or sportswear.

- Versatility in products: Beyond apparel, sublimation opens doors to various products like mugs, mouse pads, keychains, and more, anything with a polyester or specially coated surface.

What Can You Do with Screen Printing?

Screen printing, known for its rich, opaque color application, works best for designs that need bold colors and can be repeated across different surfaces. Here’s when and why you’d choose screen printing:

- Bold, solid colors: Screen printing works well with designs that use solid colors rather than gradients. If you’re aiming for vibrant, eye-catching logos or patterns on t-shirts, hoodies, or even tote bags, screen printing can achieve that crisp, saturated look.

- Ideal for cotton and fabric variety: This technique performs best on natural materials like cotton and cotton blends, so it’s commonly used for apparel. It also applies well to darker fabrics where you want the colors to pop.

- Cost-effective for bulk orders: Screen printing requires creating a stencil, which can make it more economical for large runs of the same design. This makes it a go-to method for printing team uniforms, event merchandise, or corporate apparel where consistency is key.

Which Method is Right for Your Product?

Therefore, to choose between sublimation and screen printing, consider both your product type and the design’s requirements:

- For photo-quality images and detailed designs on synthetic materials, go with sublimation.

- For bold, solid colors on natural fabrics, screen printing will give you rich color with a cost-effective approach for larger quantities.

Key Takeaway

Above, I’ve outlined the key differences between sublimation vs screen printing to help you choose the right method for your needs. After reading this, Mega Digital hope that you have a better idea of which process works best, depending on whether you need vibrant prints or bold, durable designs.