Are you confused about choosing between screen printing vs heat press for your upcoming project? Both methods offer unique advantages, but which one works best for your needs? In this blog post, I will compare the two printing techniques based on design flexibility, production speed, cost, durability, and more to help you find your best fit.

What is Screen Printing?

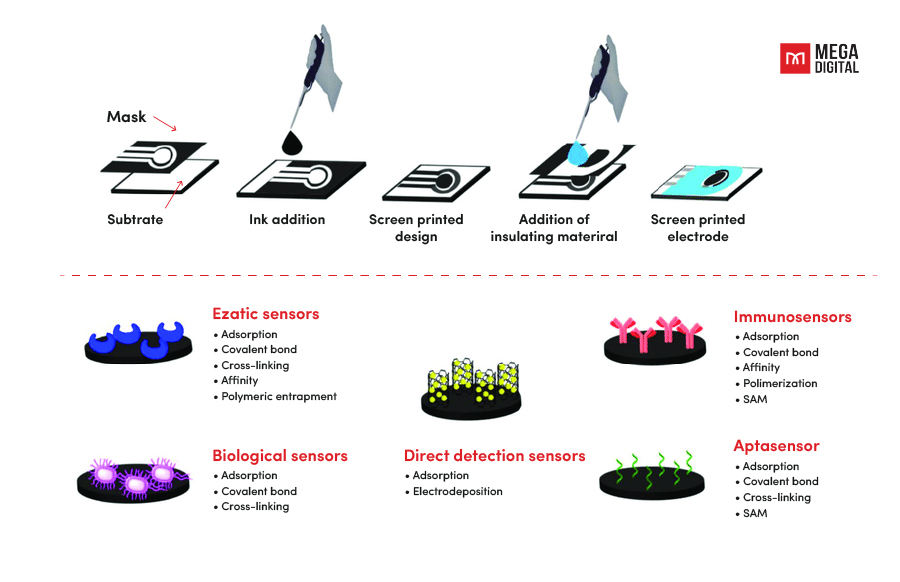

Screen printing, also known as silk screening, is a traditional POD technique that has stood the test of time. It involves creating a stencil, or “screen,” to apply layers of ink to a surface. This process works well on a variety of materials, such as fabric, paper, and even wood or metal.

The process starts with preparing the screen using a light-sensitive emulsion. Once the stencil is ready, ink is pressed through the mesh screen onto the material using a squeegee.

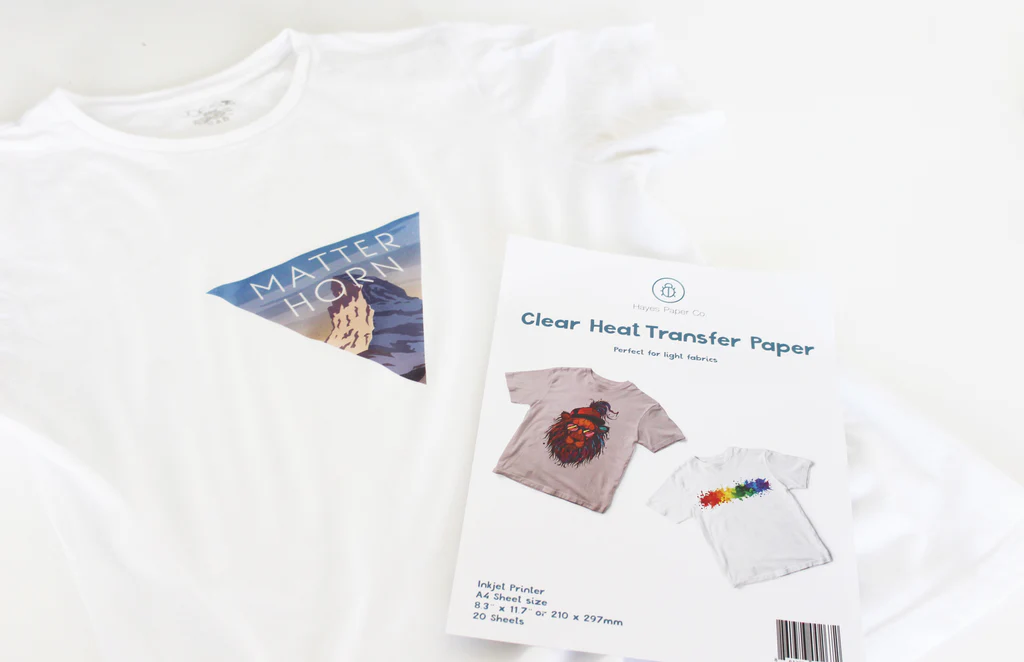

What is Heat Press?

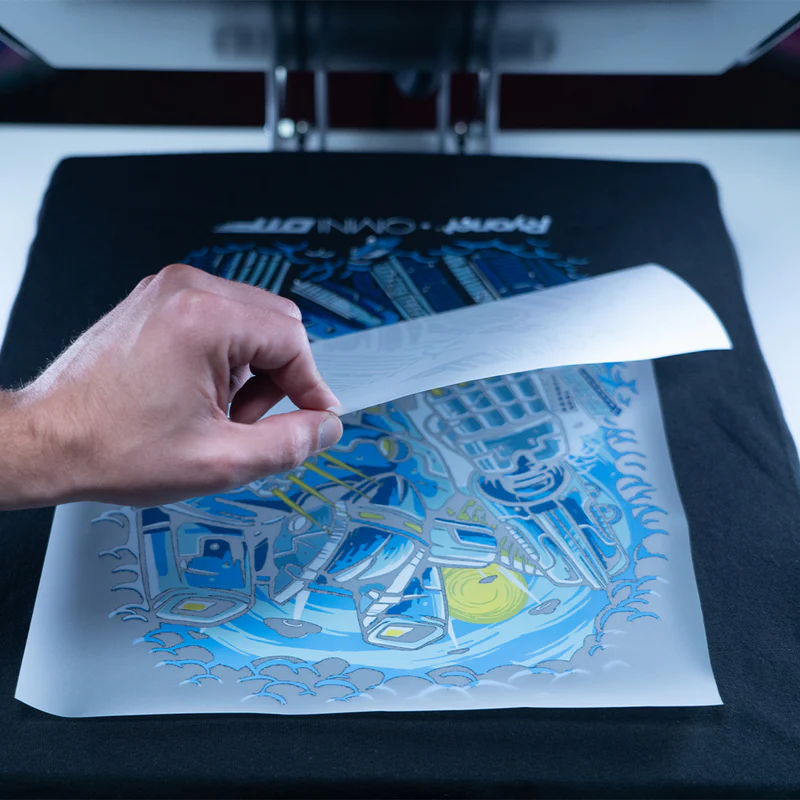

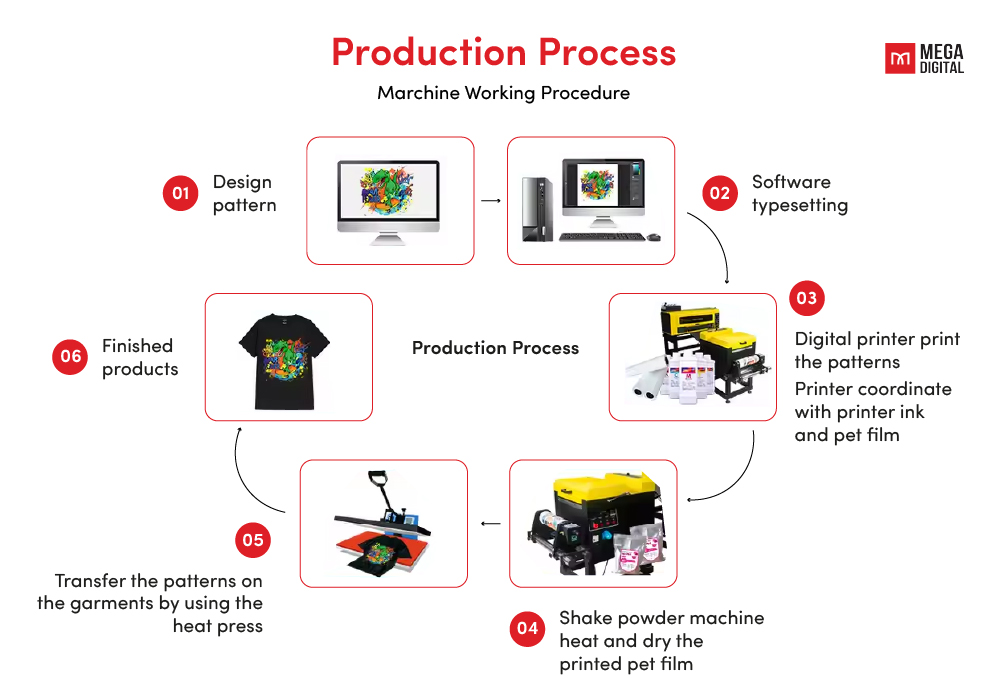

Heat press printing, on the other hand, is a more modern and versatile approach to printing. This method uses heat and pressure to transfer a design from vinyl or a transfer paper onto a surface, typically fabric. It’s like ironing, but with professional-grade equipment that ensures even application and precision.

There are different types of heat press methods, including vinyl heat transfer and sublimation. While vinyl transfer involves cutting out designs from sheets of vinyl and then pressing them onto the material, sublimation uses a special ink that turns into gas under heat, bonding directly with the fabric.

Key Difference Between Screen Printing vs Heat Press

Now you know the general concept about screen printing vs heat press, let’s dive deeper into how screen printing and heat press compare across critical factors to help you choose the right method for your project.

#1 Design Flexibility

When deciding between screen printing and heat press, design flexibility can significantly impact the final product. Let’s explore which method is better suited for your specific design needs.

Screen Printing

Screen printing is ideal for bold and simple designs with minimal color variations. For example, a company logo with one or two solid colors or a simple text-based design works perfectly with this method.

However, for designs with multiple colors or intricate details, the process becomes less efficient because each color requires a separate screen. This adds to both the cost and complexity, making fine details, gradients, or photo-like images difficult to achieve.

Despite these limitations, screen printing excels in producing vibrant and durable prints that stand the test of time.

Heat Press

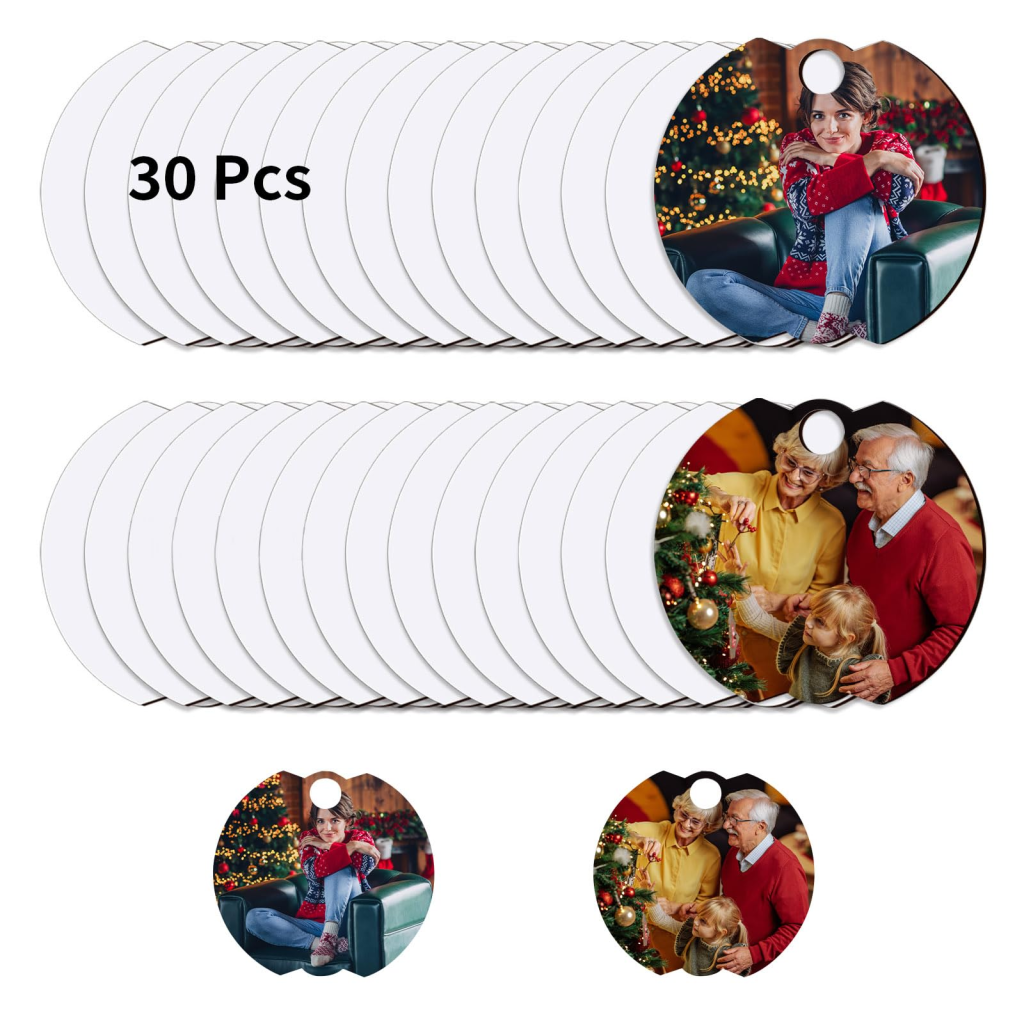

Heat press method is the go-to option for intricate and colorful designs. This method can easily replicate gradients, shading, and photo-realistic images, making it ideal for creative projects like custom artwork or photo prints on apparel.

Unlike screen printing, heat press doesn’t require a separate setup for each color, which allows for the seamless application of complex patterns or multi-color graphics. For example, a family reunion t-shirt featuring a full-color family portrait can be executed with ease and precision using heat press.

Conclusion

For detailed, colorful designs or projects requiring photographic quality, the heat press offers unmatched flexibility and ease of use. On the other hand, screen printing is an excellent choice for simple, bold designs with longevity in mind, such as branding-focused apparel or minimalist prints.

#2 Production Speed

Speed is another crucial factor, especially for businesses with tight deadlines or high-volume orders. Depending on the scale and complexity of your project, production time can vary greatly between screen printing and heat press. Here’s a look at how each method performs when it comes to meeting deadlines.

Screen Printing

Screen printing stands out for its efficiency in high-volume production. Once the screens are prepared, the process allows for rapid, consistent printing of large batches.

For example, a 100-shirt order can be completed in 1–2 hours, depending on the design and the number of colors. The setup involves creating separate screens for each color, which may take 2–3 hours, but this upfront time is negligible for bulk orders.

This makes screen printing perfect for time-sensitive projects, such as producing hundreds of event t-shirts or promotional apparel on tight deadlines.

Heat Press

When compared to screen printing, heat press printing is inherently slower because each item requires individual attention. Each design must be aligned, pressed, and cooled, which typically takes 2–5 minutes per item. Therefore, the manual process becomes a bottleneck for larger orders.

For instance, completing a 100-piece order could take 5–8 hours, depending on the design complexity and operator skill. Therefore, this method works well for smaller orders of fewer than 50 pieces or for projects requiring unique personalization, such as team jerseys with names and numbers.

Conclusion

When speed is crucial for large-scale production, screen printing is the faster and more efficient choice. For smaller, one-off orders or personalized designs, the heat press offers unmatched flexibility, even though it sacrifices production speed.

>>> Read more: Sublimation vs Screen Printing: Which One is Right for You?

#3 Bulk Creation

When it comes to scaling production for large orders, the efficiency and cost-effectiveness of your chosen method become more important. Here’s how screen printing and heat press compare in terms of handling large volumes of items.

Screen Printing

Screen printing is the preferred choice for bulk production due to its efficiency after setup. Once the screens are prepared, the printing process is quick and consistent, making it ideal for orders of 100 pieces or more.

For example, creating 500 branded t-shirts for a corporate event can significantly lower the cost per unit, often dropping to as little as $1–$3 per item, depending on the design and materials.

Additionally, the setup costs, which range from $50–$200 per screen, are easily offset by the large order size. This makes screen printing highly scalable and cost-effective for businesses or events needing standardized designs in large quantities.

Heat Press

Heat press printing is better suited for smaller orders due to its time-intensive nature. Each item must be individually placed, pressed, and aligned, which increases labor costs and slows production.

For example, producing 50 customized team jerseys with unique names and numbers can take hours, with costs per item ranging from $5–$7.

Heat press is practical for low-quantity projects requiring unique or highly customized designs but becomes inefficient and expensive for larger orders.

Conclusion

Screen printing is the best choice for bulk orders exceeding 100 pieces due to its scalability and reduced costs per item. On the other hand, the heat press works for smaller batches or personalized items, such as customized jerseys or one-off designs, but is not practical for high-volume projects.

#4 Durability of Prints

When it comes to durability, the longevity of your design is crucial, especially for items that will be subjected to frequent washing or heavy wear. the durability of your print method is a key factor to consider whether you need prints that will endure the rigors of daily use or you’re looking for something that can withstand just a few washes.

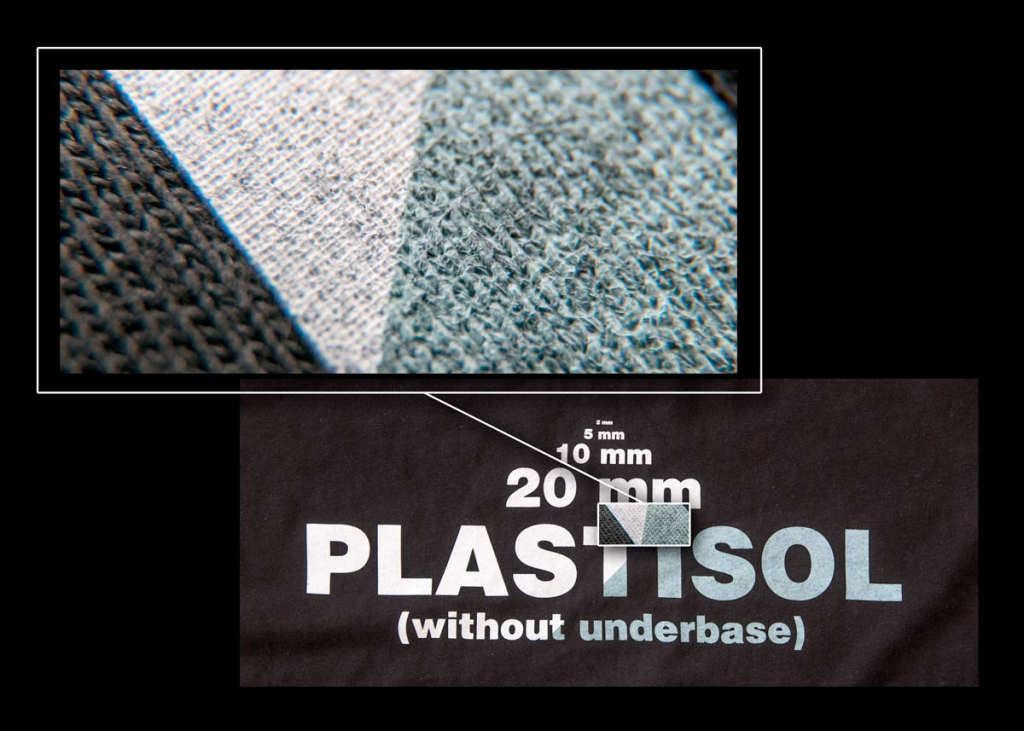

Screen Printing

Screen printing is known for its exceptional durability, making it the go-to choice for items that will see heavy use and frequent washing. The ink penetrates the fabric, creating a thick, vibrant layer that holds up well over time without cracking or fading.

For example, screen-printed athletic jerseys or work uniforms can withstand the rigors of daily wear and repeated wash cycles. Additionally, it’s ideal for cotton or cotton-blend fabrics, where the ink bonds seamlessly for lasting quality.

Heat Press

Heat press prints are generally less durable, especially when applied to cotton or other natural fibers. With heat press, your designs may start to fade, crack, or peel after 25–30 washes, particularly if not cared for properly (e.g., washing in hot water or tumble drying).

However, sublimation printing, a type of heat press used on polyester, is an exception. Sublimation designs become part of the fabric itself, ensuring they won’t fade or peel. For instance, sublimated sports jerseys or promotional polyester tote bags often retain their vibrancy and integrity for years.

Conclusion

For maximum durability, screen printing is the clear winner, especially for cotton-based fabrics or items exposed to frequent washing and wear. While heat press can deliver long-lasting results on polyester through sublimation, it’s generally less resilient on other materials.

#5 Color Options

Color plays a critical role in defining the visual appeal and effectiveness of your design. Choosing the right print method can ensure that your design’s colors come out vibrant and crisp. Let’s dive into how each method handles color.

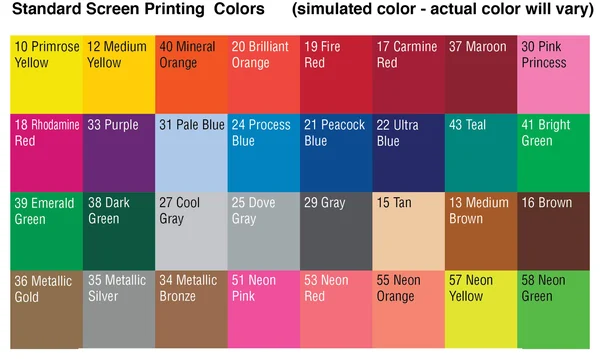

Screen Printing

Screen printing is known for producing vibrant, high-quality colors that pop, especially on darker fabrics. However, this process is less suitable for complex, multi-color designs. Each color requires its own screen, which increases setup time and cost. As a result, screen printing is ideal for designs with:

- Solid, bold colors like red, blue, yellow, and black.

- Simple two-tone graphics for logos or slogans.

- Opaque colors that need to stand out on darker materials (e.g., white or metallic inks).

- Neon or specialty inks for eye-catching designs on promotional items.

Heat Press

Heat press printing shines when it comes to multi-color and gradient-rich designs. It doesn’t require additional setup for complex patterns, making it perfect for intricate or photo-realistic images. Heat press works best for:

- Gradient colors and blended shades, like ombre effects.

- Photographic prints that require precision and detail.

- Custom color palettes tailored to individual projects.

- Digital artwork with sharp details and smooth transitions between hues.

Conclusion

Heat press is the better choice for designs with unlimited colors, gradients, or photo-realistic details. However, if you’re working with bold, high-contrast colors or want a cost-effective solution for simple designs, screen printing delivers exceptional results.

#6 Fabric Compatibility

Both screen printing and heat press have their ideal fabric types that ensure optimal print quality and durability. Let’s look at how each method handles different materials.

Screen Printing

Screen printing is best suited for natural fibers and cotton-based fabrics. The ink bonds well with these materials, providing vibrant, long-lasting prints that can withstand frequent washing. Here are some fabric recommendations for screen printing:

- Cotton: Ideal for bold, simple designs. Commonly used for t-shirts, hoodies, and promotional items.

- Cotton Blends: Works well for comfortable, durable items like custom shirts or bags. The ink adheres well to these fabrics.

- Linen: A bit more challenging but still workable for simple, bold designs.

Additionally, I don’t recommend you use screen printing for these materials:

- Nylon: The ink doesn’t bond well with nylon and can easily fade.

- Polyester (Non-Sublimation): Polyester can be more challenging for screen printing, especially for intricate designs, as the ink sits on top of the fabric and may crack or peel over time.

Conclusion

Screen printing is your best bet for durability and vibrant color payoff for cotton and cotton blends while heat press (specifically sublimation printing) is ideal, providing the best long-lasting results for polyester and synthetic blends.

Heat Press

Heat press printing is more versatile and can be used on a wider variety of fabrics. The heat press works well with synthetic and natural fabrics, but the print’s longevity varies. Here are some fabric that I would recommend for heat press:

- Polyester: Ideal for sublimation printing. The ink becomes part of the fabric, providing vibrant, durable prints that won’t fade or peel, making it perfect for sports jerseys or custom apparel.

- Cotton: Heat press works for cotton, but the print may not be as durable as screen printing. Designs on cotton items might fade over time with repeated washing.

- Poly-blends: These fabrics work well with heat press, providing good color retention and durability.

- Nylon: Heat press works effectively on nylon fabrics, making it ideal for bags, jackets, and other outerwear items.

- Acrylic: This synthetic fiber also works well with heat press, delivering clear and precise prints.

Yet you shouldn’t use heat press for heavy textured fabrics like denim, which have thicker, uneven surfaces, and may not allow for smooth, even heat transfers, reducing the print quality.

>>> Read more: Digital Printing vs Screen Printing: A Complete Comparison Guide

#7 Cost Comparison

When deciding between screen printing and heat press for your project, understanding the cost dynamics is crucial. Below is a detailed breakdown of how these two printing methods compare in terms of setup costs, cost per unit, and long-term investment.

| Factor | Screen Printing | Heat Press |

|---|---|---|

| Setup Costs | High: Costs can range from $50 to $200 per screen, depending on the design complexity. | Low: Setup costs typically range from $10 to $30 per transfer. |

| Cost Per Unit (Low Qantity) | Expensive: Around $8–$10 per item for small runs due to setup costs. | Affordable: Approximately $3–$5 per item, ideal for short runs. |

| Cost Per Unit (High Quantity) | Low: As low as $1–$3 per item for bulk orders (500+ pieces). | Expensive: Around $5–$7 per item, as each is processed individually. |

| Equipment Investment | High: Initial equipment investment starts at $10,000–$20,000 for professional setups. | Moderate: Heat press machines cost between $300–$3,000, depending on quality. |

| Customization Costs | High: Separate screens for each design cost around $25–$50 per screen. | Low: Customization costs are minimal, averaging $1–$2 per design. |

Conclusion

For small, customized orders with intricate designs, heat press is the more cost-effective solution. However, for larger, repetitive projects requiring bold designs, screen printing delivers greater cost efficiency.

Screen Printing Vs Heat Press – Which One Is Better?

As I’ve mentioned above, both methods have distinct strengths and weaknesses. To make your decision easier, here’s a checklist table summarizing the above comparison of screen printing vs heat press:

| Feature | Screen Printing | Heat Press |

|---|---|---|

| Bulk Orders | Yes, cost-efficient for 100+ pieces. | Not ideal, slower for large quantities. |

| Durability | Excellent for long-lasting, high-use designs. | Good for polyester sublimation but less durable on cotton. |

| Design Complexity | Limited to bold, simple designs with few colors. | Handles gradients, intricate patterns, and photo quality. |

| Setup Costs | High due to separate screens for each color. | Low, minimal setup required for any design. |

| Speed for Small Runs | Time-intensive setup for small orders. | Quick, ideal for one-offs or small projects. |

| Color Range | Vibrant for solid, bold colors. | Unlimited, including gradients and multi-color designs. |

What is Heat Transfer Best For?

Heat press excels when your project demands flexibility, detail, or smaller production runs. This method is specifically suited for situations where personalization and intricate designs are essential.

Here are some cases when heat press is the ideal choice:

- Custom designs: Perfect for personalized items like jerseys with names or numbers.

- Photo-realistic or detailed patterns: Handles gradients, shading, and photographic elements effortlessly.

- Low-quantity projects: Best for small batches of 50 or fewer items, where setup time and costs are minimal.

- Polyester fabrics: Sublimation heat press offers vibrant, durable results on polyester materials.

What is Screen Printing Best For?

Screen printing works well with bulk production and durable, bold designs, making it a go-to for businesses, events, or branding projects requiring large orders. Its ability to produce consistent quality across hundreds of items while keeping per-unit costs low makes it highly practical for long-term use and repeat orders.

If you want to use screen printing, consider these cases::

- Bulk orders: Ideal for large runs of 100+ items, such as corporate apparel or promotional merchandise.

- Simple, bold designs: Logos or graphics with up to 3–4 solid colors work exceptionally well.

- Cotton or cotton blends: Produces highly durable prints that withstand frequent washing and wear.

- Long-lasting designs: Perfect for items subject to heavy use, like uniforms or sportswear.

Conclusion

Above, I gave you a detailed comparison of screen printing vs heat press, outlining their strengths and ideal uses. I hope you can choose the method that best suits your design, quantity, and budget needs to gain the best benefits for your POD business.