Are you considering digital printing vs screen printing for your business? Each method offers distinct advantages depending on your specific needs. I’ll break down the key differences and guide you on when to choose each option, helping you make the best choice for your print-on-demand needs.

What is Digital Printing?

As POD businesses seek innovative solutions to meet their printing needs, digital printing has emerged as a powerful alternative to traditional methods. This modern approach not only streamlines the printing process but also enhances quality and sustainability.

Digital printing is a modern printing method that involves the direct transfer of digital images onto various media, such as paper, fabric, or vinyl.

Unlike traditional printing methods that require physical plates or screens, digital printing utilizes digital files, allowing for quick setup and production. This technology enables a wide range of applications, from printing high-quality photos to producing intricate designs on customized apparel and promotional products.

What is Screen Printing?

While digital printing is gaining popularity, screen printing remains a tried-and-true method that has been around for decades. This traditional technique offers unique advantages that make it a go-to choice for many POD businesses, particularly when it comes to producing bold designs and vibrant colors for apparel collections.

Screen printing, also known as silk screening, involves transferring ink through a mesh screen onto a substrate, such as such as clothing or branded merchandise. In this process, a stencil is created for each color in the design, which allows the ink to be applied precisely where it’s needed.

This method is highly versatile and can be used for everything from clothing to signage (commonly used for bulk orders in e-commerce stores), making it a favorite among manufacturers and artists alike.

The Key Differences Between Digital Printing vs Screen Printing

Choosing between screen printing and digital printing depends on your specific needs, as each method has distinct advantages. In this part, I will take a closer look at how they differ based on several key factors.

Order Quantity

Digital Printing

Digital printing is ideal for smaller orders or one-off items. It’s perfect for POD products where personalization is key, such as limited-edition items in your e-commerce catalog.

Since it doesn’t require any physical setup, this method allows for on-demand printing, making it a cost-effective choice for your business.

In fact, research from industry studies shows that digital printing is more economical for orders under 50 pieces. For small quantities like this, the cost savings from avoiding setup fees can be significant; while traditional screen printing might add an upfront setup cost of $20–$50 per color, digital printing doesn’t have such fees.

For example, if you want to print 10 custom T-shirts with different names and numbers on each, digital printing allows you to personalize each item individually without any additional setup costs. This flexibility makes it a popular choice for small, custom orders or limited-edition products.

Screen Printing

With screen printing, the setup process includes creating separate screens for each color in the design, which takes time and resources. However, once the setup is complete, it becomes cost-effective for large orders, as the cost per item decreases with higher quantities

Generally, screen printing becomes the more economical choice when ordering around 100 or more items. Industry data shows that for orders of 100+ pieces, the per-unit cost can decrease by up to 50% compared to digital printing.

Therefore, many online apparel shops use screen printing to produce branded merchandise in large quantities.

For example, if a company needs 500 identical T-shirts with a single logo design, screen printing becomes more economical because the initial setup cost is spread across a large quantity, reducing the overall cost per shirt.

Conclusion

For smaller or personalized orders, digital printing is generally more economical. On the other hand, for larger orders with the same design, screen printing offers better cost efficiency.

>>> Read more: What is DTG Printing? A Comprehensive Guide for Beginners in POD

Durability

Digital Printing

Digital prints are durable but may not be as resilient over time as screen prints, especially with frequent washing or exposure to the elements. The thinner ink used in digital printing can fade or crack over extended use.

For instance, digital prints on T-shirts can fade slightly after multiple washes, especially on darker fabrics where the print sits on the surface. However, for products like posters or flyers that don’t experience wear and tear, digital printing’s durability is sufficient.

For this feature, digital printing is typically used for items that aren’t exposed to heavy use, such as limited-edition designs or seasonal products.

Screen Printing

Screen printing is renowned for its durability, especially on fabric, making it ideal for workwear or sportswear. The thicker inks used in screen printing bind more firmly to fabric, which helps the print withstand frequent washing and outdoor exposure without fading or cracking.

For instance, screen printing is commonly used on sports jerseys for professional teams, such as the NBA or NFL, where durability is crucial. The bold team logos, player names, and numbers need to remain bright and intact despite the intense physical activity and repeated washing cycles after each game.

Thanks to screen printing, these details maintain their quality throughout the season, supporting the brand and player recognition with a vivid, professional look.

Conclusion

If you need a print that can endure frequent washing and heavy use, such as workwear or uniforms, screen printing offers greater durability. In contrast, digital printing is suitable for items with less exposure to wear.

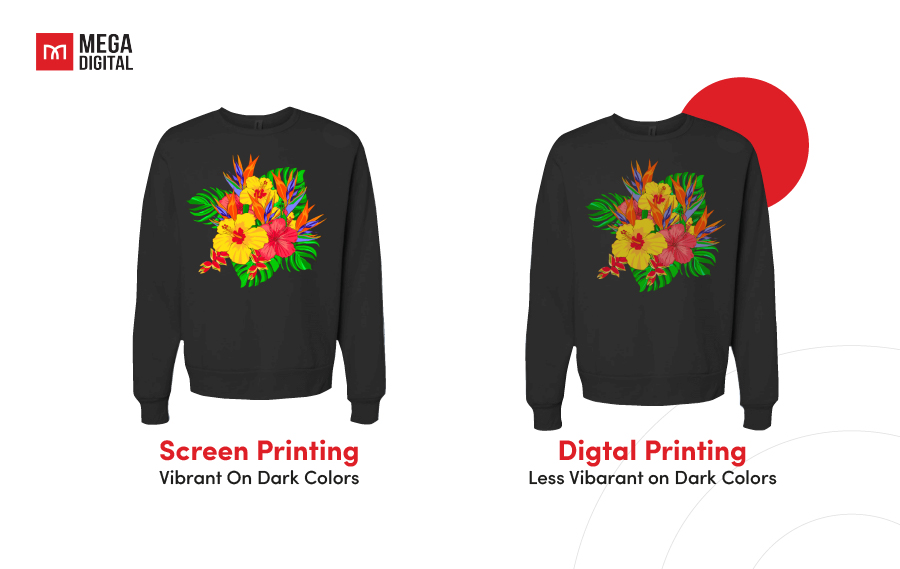

Vibrancy

Digital Printing

Digital printing is known for its exceptional color vibrancy, especially on light-colored materials, and it’s ideal for complex designs that feature multiple colors, gradients, and even photorealistic images.

However, on darker fabrics, the colors may appear less vibrant since the ink lacks the opacity to fully cover the darker background.

For example, a digital print of a colorful, gradient-filled sunset on a white T-shirt will capture each shade and transition vividly, giving the design a crisp and eye-catching appearance. In contrast, the same sunset design on a dark blue T-shirt may appear more subdued, with the colors losing some brightness.

This makes digital printing a popular choice for custom photo T-shirts or designs that require a high level of detail – projects that would be challenging to recreate with screen printing.

Screen Printing

Screen printing is ideal for achieving vibrant, bold colors, even on dark fabrics, and is commonly used for brand logos or simple, bold designs. This method uses thick, opaque inks that sit on top of the material, allowing colors to appear rich and vivid regardless of the fabric’s background color.

This method is particularly advantageous for e-commerce stores selling dark-colored T-shirts or promotional items where color intensity is essential.

For example, imagine a red sports team logo printed on a black T-shirt for a fan event. Using screen printing, the red ink fully covers the dark fabric, ensuring that the logo looks bright and striking rather than faded or dull.

This vibrant finish is why screen printing is commonly used for branding on dark-colored apparel it provides a professional, eye-catching look that holds up well to frequent wear and washing.

Conclusion

For vibrant colors, especially on dark materials, screen printing tends to provide richer, bolder results. Digital printing can still be vibrant, but it may be best suited for lighter backgrounds.

Design Color

Digital Printing

Digital printing excels with designs that involve complex color schemes, gradients, and photorealistic images. There’s no limit on the number of colors, making it perfect for multi-color designs.

Digital printing is perfect for complex designs with a wide color range, gradients, or photorealistic images, as it doesn’t require separate screens for each color.

For example, a detailed graphic with a full-color image of a cityscape can be printed directly from the digital file onto a T-shirt or poster without additional setup, capturing every color and gradient exactly as designed.

Screen Printing

Screen printing requires a dedicated screen for each color in the design, making it more time-consuming and costly for complex, multi-color projects. Each additional color requires its own screen and setup, so intricate designs with multiple colors can quickly drive up production costs and setup time.

This process is therefore best suited for simpler designs with a limited color palette, where bold colors and clean lines are prioritized over detailed images.

You should opt for screen printing if your design is simple, with few colors, and you need a durable, vibrant finish. It’s ideal for logos, bold graphics, and designs that can benefit from the thicker inks used, which hold up well on high-wear items like uniforms and promotional apparel.

Conclusion

If your design requires intricate details and a wide color range, digital printing is ideal. For simpler, bold designs with fewer colors, screen printing can be highly effective.

Sustainability

Digital Printing

Digital printing is known for its eco-friendly benefits, largely because it uses water-based inks, which have a much lower environmental impact than the petroleum-based inks used in some other printing methods.

This method also minimizes waste by applying only the amount of ink necessary for each print, eliminating the excess that can occur in other printing techniques. Additionally, digital printing requires fewer resources and avoids harsh chemicals, resulting in a lower carbon footprint for each printed item.

Its highly eco-friendly feature aligns with the goals of many sustainable e-commerce brands and it’s a popular choice for companies that prioritize green practices in their POD business model.

Screen Printing

Screen printing has traditionally created more waste because it involves a setup process where screens need to be prepared and cleaned with chemicals.

But in recent years, many companies have found ways to make this process greener. They’re now using eco-friendly inks like soy-based or water-based inks, which are biodegradable and reduce environmental harm.

Additionally, some printers also recycle water and have switched to non-toxic cleaners to further reduce their impact.

For instance, Everlane, known for its sustainable approach, partners with screen printers that use these eco-friendly practices. This lets them keep producing bold, high-quality designs while staying committed to the environment, which is a great approach that appeals to customers looking for more responsible brands.

Conclusion

If environmental impact is a primary concern, digital printing is generally the greener choice. However, screen printing can also be made sustainable with eco-conscious practices.

Design Consistency

Digital Printing

Digital printing offers a high level of consistency, ensuring that each print perfectly matches the original digital file. This makes it an ideal choice when you need every item to look exactly the same, such as for branded merchandise.

For example, if a company is printing a series of tote bags with a detailed logo that includes multiple colors and fine lines, digital printing guarantees that each bag will display the logo with the same precision, color accuracy, and quality—whether it’s the first or the thousandth print.

This reliability is particularly valuable for brands that prioritize a consistent look across all products, as it ensures accurate brand representation every time.

Screen Printing

Screen printing can introduce subtle differences between each print, as it involves some manual adjustments, like ink application and alignment. These slight variations can give each item a one-of-a-kind, handcrafted quality, which adds character and uniqueness.

For example, a small business printing a line of limited-edition t-shirts may choose screen printing to create a more artisanal feel. Each shirt might have minor differences in color depth or line placement, which can appeal to customers who appreciate a more personal, unique touch in their products.

However, brands that need exact consistency, like logos or standardized designs, might find this lack of uniformity less suitable.

Conclusion

Digital printing is the go-to choice for consistent design quality, while screen printing adds a slightly unique touch to each item, which some brands may find appealing.

Cost

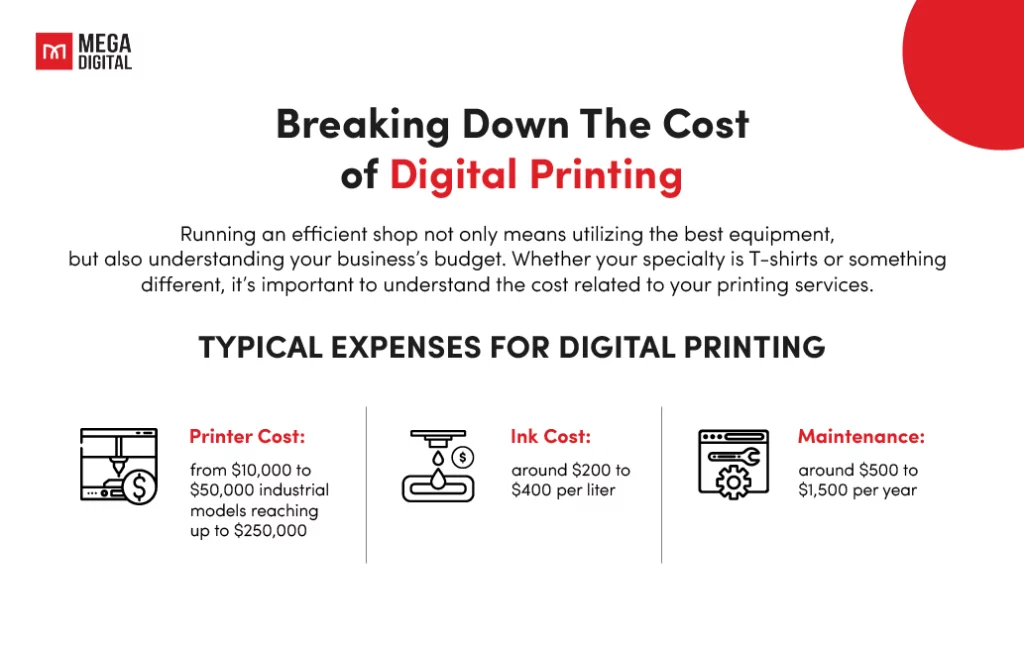

Digital Printing

Digital printing tends to have a lower setup cost, making it ideal for small-batch orders and customization. For e-commerce businesses, this means lower upfront investment, as there’s no need for screen creation. Here’s a breakdown of common expenses:

- Printer Cost: High-quality digital printers typically range from $10,000 to $50,000, with industrial models reaching up to $250,000. These printers can handle a wide range of designs without additional setup costs for each print.

- Ink Cost: Digital printers use water-based inks, costing around $200 to $400 per liter. However, they are more efficient, using only the exact amount of ink needed per print. Ink cost per shirt might range from $0.10 to $0.50 depending on color usage.

- Maintenance: Digital printers require regular upkeep, like print head cleaning and software updates, averaging around $500 to $1,500 per year.

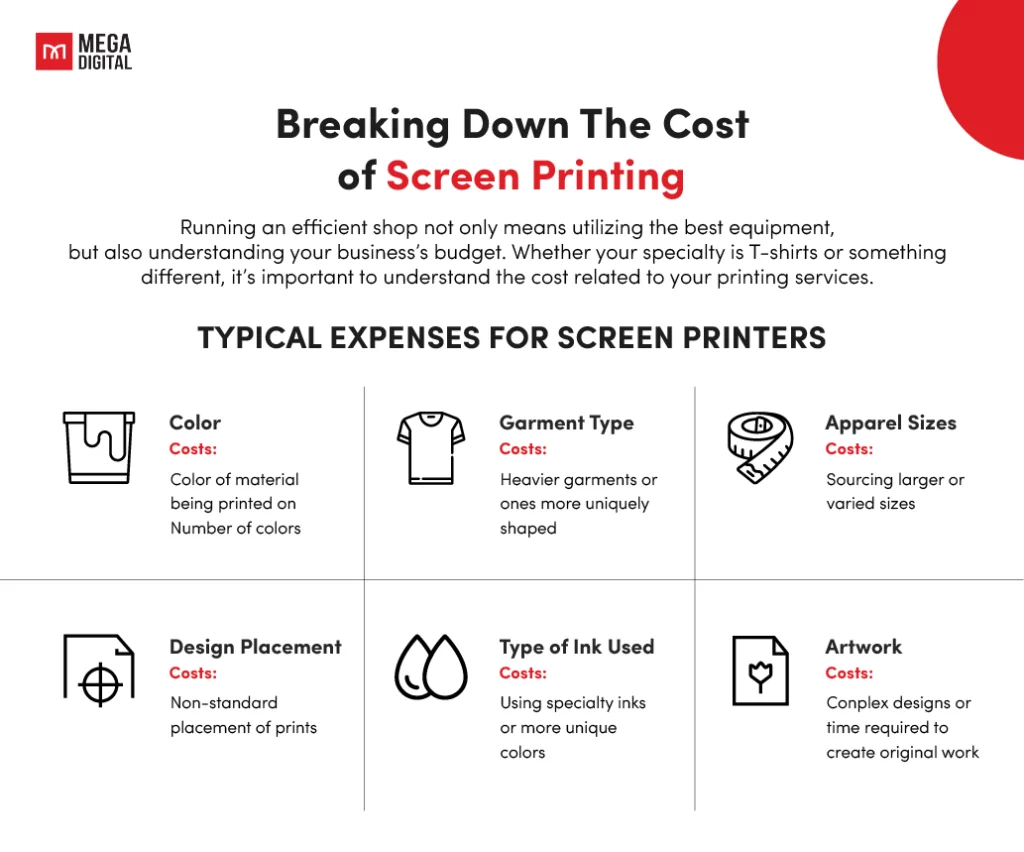

Screen Printing

Screen printing has higher operating costs due to more complex processes and equipment, so it becomes more cost-effective for large order volumes, with costs decreasing as production increases.

With this feature, e-commerce businesses focused on bulk printing of popular items may benefit from the economies of scale offered by screen printing.

- Screen Printer Cost: Basic screen printing equipment starts around $5,000, while professional-grade setups can cost $30,000 or more. Automated screen printing presses, which improve efficiency for larger orders, can exceed $50,000.

- Ink Cost: Plastisol or water-based inks for screen printing cost around $50 to $100 per gallon, with average ink costs per shirt ranging from $0.05 to $0.30 depending on the design and coverage.

- Screen & Chemical Costs: Each screen costs around $20 to $50 and needs cleaning and re-coating for every new design, adding to the operating cost. Chemicals for cleaning and reclaiming screens add roughly $0.10 to $0.30 per print.

- Labor and Setup Time: Screen printing requires manual setup and alignment, with setup times averaging 15-30 minutes per design, which increases labor costs, especially for small orders.

Conclusion

To sum up, digital printing is ideal for small, custom orders with lower setup costs, while screen printing is more cost-effective for large runs due to its scalability.

Digital Printing vs Screen Printing: Which Method is Right for Your Business?

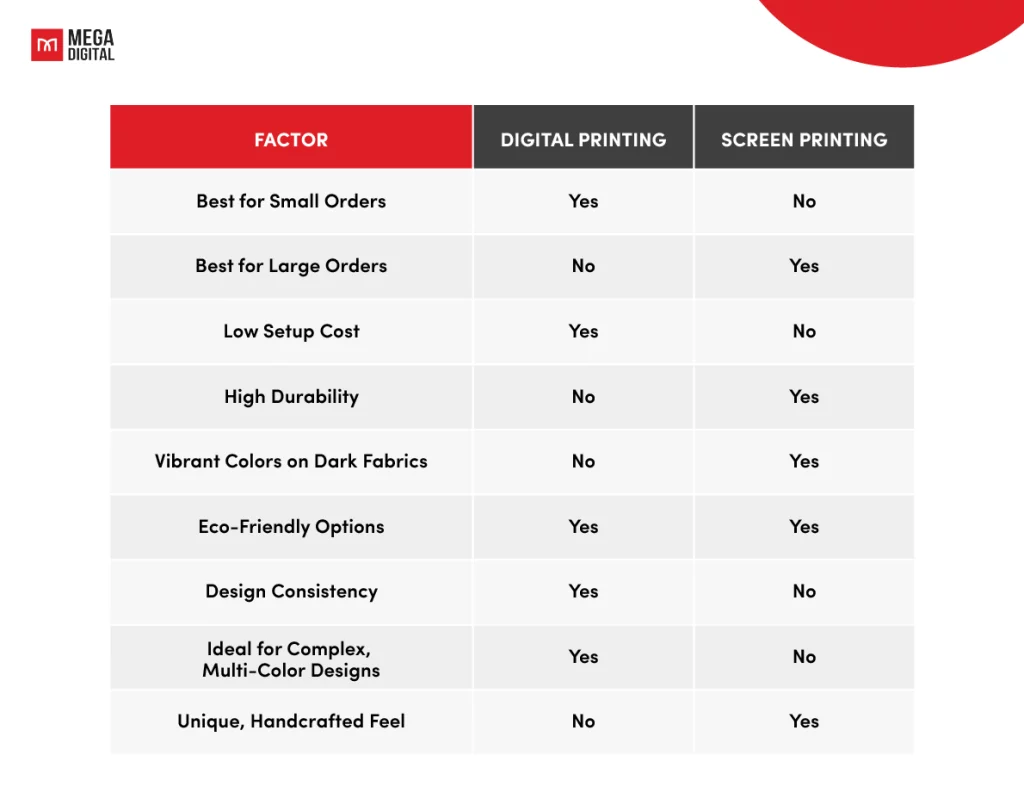

If you’re still unsure which printing method is right for you, I have a comparison table to help you simplify your decision. This summary highlights the key factors of each method, so you can quickly identify which option meets your project needs:

When to Use Each Method?

In short, the choice between digital printing vs screen printing comes down to your specific project needs.

For brands that prioritize design precision and consistency across products, digital printing is the go-to method. If you have a smaller order, need customization, or have complex designs with multiple colors, this method is also worth considering. Additionally, digital printing is also great if you want lower setup costs and a quick turnaround, as there’s no need to prepare screens.

On the other hand, you can choose screen printing when you’re producing a large order with the same design, as its setup cost becomes more economical at higher quantities.

This method is also ideal if you need bold, vibrant colors, especially on darker fabrics, where screen printing’s thicker inks can create a bright, striking look. Screen printing is also perfect for items like uniforms, sports apparel, or other products that will undergo frequent washing and wear because of its durability.

Additionally, if your brand values a unique, handcrafted quality, this method provides subtle variations that give each item an artisanal appeal, making it a great fit for brands seeking a more personal, crafted look.

Conclusion

Above, I gave you a detailed comparison of digital printing vs screen printing. By choosing the right method, I hope you can balance cost and quality to deliver professional, eye-catching results and grow your POD business.