What is heat transfer printing? If you’re looking to add vibrant, durable designs to custom products, heat transfer printing is a great option. In this guide, I’ll walk you through what heat transfer printing is, how it works, its benefits, and the best ways to apply it to your business or creative projects.

Contents

What Is Heat Transfer Printing?

Heat transfer printing is a method that uses heat and pressure to transfer designs onto various surfaces, such as fabric, ceramics, or metal. Essentially, the design is printed onto a special transfer paper or vinyl and then applied to the desired item using a heat press. As a result, you get a detailed and long-lasting print that feels professional.

This technique is widely embraced in POD industries like apparel, promotional products, and custom merchandise. Thanks to its ability to handle intricate details, like gradients and photographs, it’s a favorite among creatives and entrepreneurs alike.

Heat Transfer Printing Process

The heat transfer printing process is straightforward but highly effective. To understand its popularity, let’s break down the process step by step:

- Design Creation: First, your artwork is prepared digitally and printed onto transfer paper or vinyl using either a standard printer or specialized equipment.

- Preparation: Next, the material to be printed (like a t-shirt or mug) is cleaned and positioned on the heat press machine to ensure an even transfer.

- Transfer Application: After that, the transfer paper is placed on the item, and the heat press is activated. Heat and pressure are applied for a set time, typically 10–30 seconds, depending on the material and transfer type.

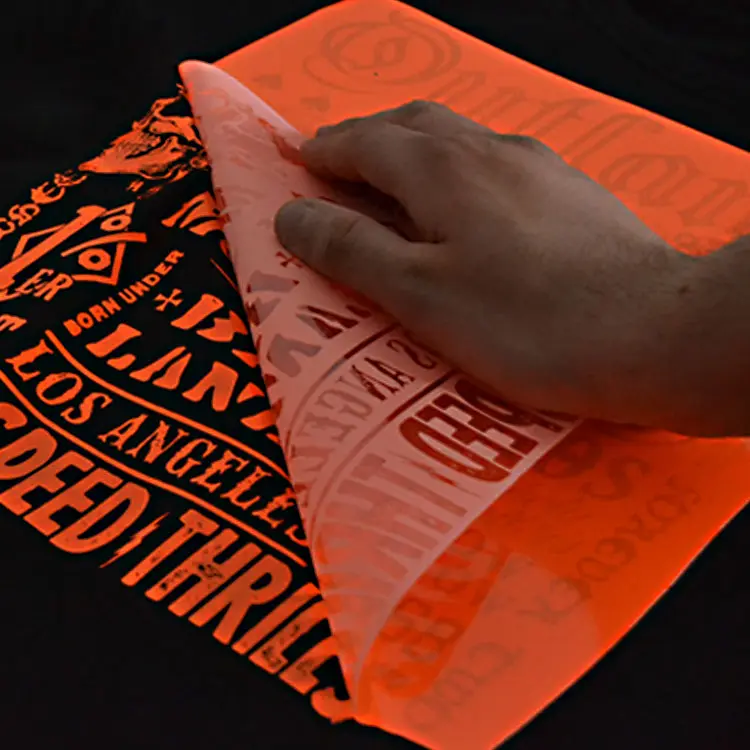

- Peeling and Finishing: Finally, the transfer paper is carefully peeled away, leaving the design adhered to the material.

Benefits Of Heat Transfer Printing

Heat transfer printing method is best suitable for those looking to create professional-quality products with ease. This technique has plenty to offer, from vibrant prints to unmatched versatility. Let’s explore its key benefits to see why it’s so widely used.

High-quality prints with vibrant colors

The heat transfer process ensures that colors remain rich and sharp because it uses heat and pressure to embed inks deeply into the material. This results in designs that are not only visually striking but also resistant to fading, cracking, or peeling.

This benefit is particularly valuable for businesses and creators aiming to deliver professional-quality products as well as customers who demand durable and vibrant prints, especially in industries like fashion, promotional merchandise, and custom gifts.

>>> Read more: What is DTG Printing? A Comprehensive Guide for Beginners

Print Complex Designs with Ease

Heat transfer printing can faithfully reproduce gradients, shading, fine lines, and even photorealistic images. This precision comes from the high-pressure process that transfers every detail from the transfer paper to the substrate.

It also enables the production of sophisticated and detailed designs without compromise, appealing to customers who value uniqueness and customization. The ability to replicate complex artwork ensures the final product matches the vision, making it an excellent choice for artists, designers, and brands.

Flexibility with different materials

Heat press printing method is compatible with a wide range of materials, including fabric, ceramics, wood, metal, and even glass. This versatility is made possible by the adaptability of transfer papers and inks that bond effectively with various surfaces.

This flexibility benefits businesses operating in diverse industries. For example, companies producing apparel, promotional products, or custom home decor can streamline production by using a single method for multiple product types to reduce costs and increase efficiency.

Cost-effectiveness for small to medium runs

Unlike other methods that require large-scale production to justify setup costs, heat transfer printing is ideal for smaller batches. With minimal upfront investment in equipment and materials, creators can produce high-quality designs on demand.

This is a major advantage for small businesses, startups, and independent creators who don’t have the resources for bulk production. It allows them to test new designs, cater to custom orders, and meet customer demand without overproducing. For consumers, this means access to personalized, high-quality items at reasonable prices.

The Most Common Types Of Heat Transfers

Heat transfer printing offers various methods, each with unique strengths tailored to different needs. Let’s take a closer look at these popular methods and what sets them apart to choose the best option for your specific project.

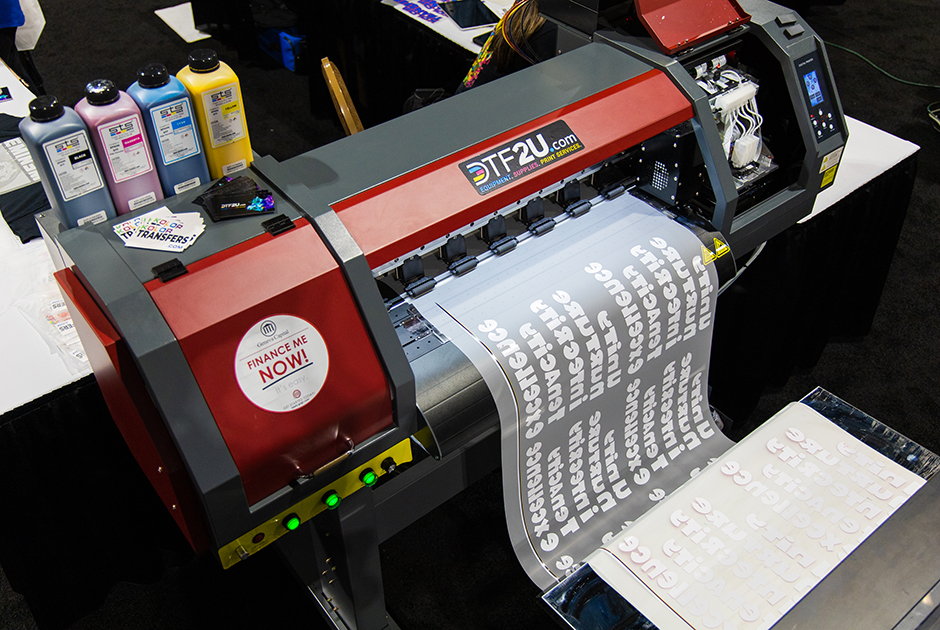

Direct-To-Film Transfers (DTF)

Direct-to-film (DTF) transfers are a modern solution that combines versatility and durability. The process involves printing designs onto a special PET film, applying adhesive powder to the back, curing it, and then transferring the design onto fabric using a heat press.

What makes DTF transfers unique is their compatibility with a wide range of fabrics, including cotton, polyester, and blends. Unlike sublimation, they aren’t limited to light-colored materials, and the prints remain vibrant and durable even after multiple washes. This method is perfect for small-scale custom orders or detailed designs requiring precise color matching.

DTF transfers are est for: Apparel like t-shirts, hoodies, and caps that need long-lasting, vibrant prints across all fabric types.

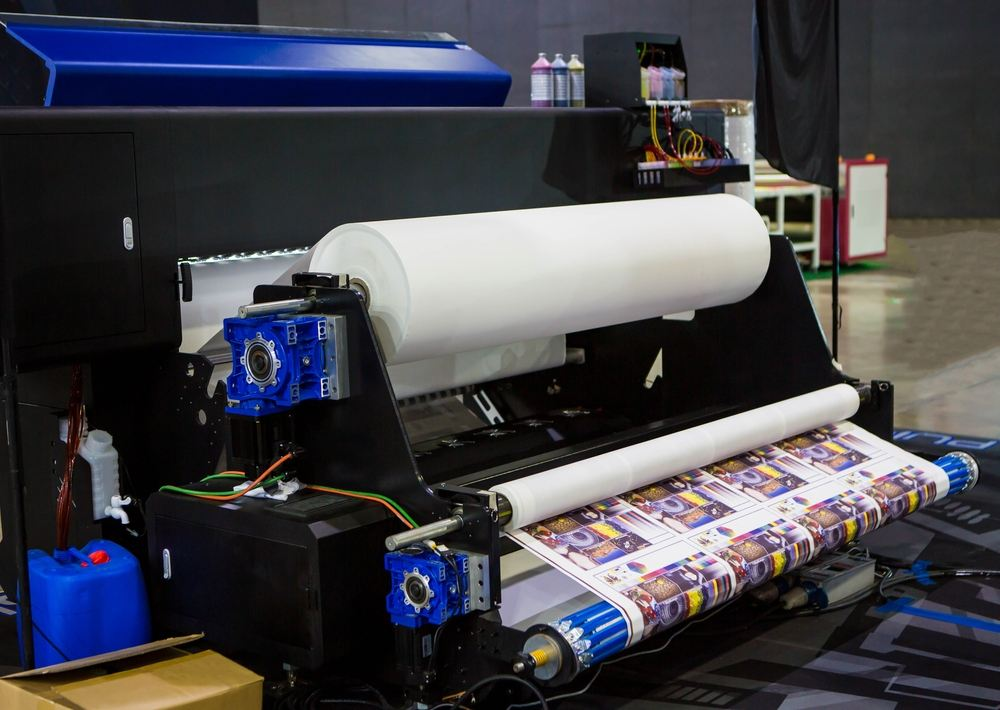

Sublimation Transfers

Sublimation transfers offer unparalleled durability by chemically bonding ink to the material, essentially embedding the design into the fabric or item. This method works by using heat to convert solid ink into gas, which then penetrates the polyester surface.

The result is a design that won’t crack, peel, or fade over time. However, sublimation has its limitations: it only works on light-colored polyester fabrics or polyester-coated surfaces like mugs, tumblers, or keychains. Despite these restrictions, it’s a top choice for creating seamless, high-quality finishes on items where the design feels like part of the material.

When using sublimation transfers, these materials are recommended: Polyester garments, promotional items, and custom gifts requiring bold, integrated designs.

Screen Printed Transfers

Screen-printed transfers combine the precision of screen printing with the flexibility of heat application. Designs are created using traditional screen printing techniques, but instead of printing directly onto the fabric, they’re transferred to a special paper that can later be applied to garments using heat.

This method is known for producing bold, high-opacity designs that stand out, even on dark fabrics. Screen-printed transfers also allow for batch printing, making them an efficient choice for bulk orders. The ability to stockpile transfers for future use adds another layer of convenience.

Screen-printed transfers work best with these fabrics: Large orders of uniforms, branded merchandise, or any product requiring sharp, high-contrast designs.

Vinyl Heat Transfers

Vinyl heat transfers use sheets of colored vinyl that are cut into specific shapes or letters using a plotter machine. These vinyl pieces are then heat-pressed onto the fabric, creating clean, solid designs with a slightly raised texture.

Vinyl is an excellent choice for personalization, such as adding names, numbers, or logos to items. Its durable nature ensures the design maintains its quality over time, even with frequent washing. However, it’s best suited for simpler designs due to the labor-intensive cutting and weeding process.

Vinyl heat transfers are best for: Sports uniforms, personalized apparel, and promotional items requiring bold, standout visuals.

Dye Sublimation

Dye sublimation is a subset of sublimation that specializes in transferring detailed, photo-quality prints. The process involves heat and pressure to infuse dye into polyester-coated materials, ensuring vibrant, sharp images.

This method is ideal for items that demand intricate designs, such as promotional merchandise or decorative products. While it shares the same material limitations as regular sublimation, its ability to deliver high-resolution results makes it a favorite for creating personalized photo gifts or corporate branding items.

I highly recommend you use dye sublimation for these cases: Photographic prints on mugs, mousepads, and other hard goods requiring exceptional detail and color depth.

>>> Read more: Screen Printing vs Heat Press: What Works Best for Your Projects?

Common Applications of Heat Transfer Printing

Heat transfer printing is a versatile method that serves a wide range of industries. Let’s explore how different sectors benefit from heat transfer printing and why it’s the go-to choice for so many creators and businesses.

Apparel (T-Shirts, Hoodies, Sportswear)

When it comes to custom apparel, heat transfer printing truly works. This method allows you to create eye-catching designs on a variety of fabrics, including cotton, polyester, and blends. Its precision also ensures every print stands out, from bold logos to detailed graphics.

What makes it even more appealing is its durability and clarity. Designs made using heat transfer printing resist fading, cracking, and peeling, which is especially important for activewear or uniforms that go through frequent washing, making them perfect for everyday apparel and sportswear.

Additionally, it’s perfect for small-batch runs, making it easy for businesses to test new designs or offer personalized products.

Promotional Products (Mugs, Tote Bags, Caps)

If you’ve ever received a branded mug or tote bag that seemed too good to give away, chances are it was created using heat transfer printing. This method is ideal for promotional items because it can handle various surfaces while maintaining a professional, high-quality finish.

For instance, sublimation transfers work perfectly on hard goods like mugs, creating vibrant designs that are scratch-resistant and dishwasher-safe. Meanwhile, tote bags and caps can feature bold logos or intricate designs using vinyl or screen-printed transfers.

The vibrant, professional finish of heat transfer prints enhances the appeal of promotional items, making them more likely to be retained and used by recipients.

Customized Gifts And Merchandise

Personalization is one of the hottest trends in retail, and heat transfer printing is the ideal tool for creating one-of-a-kind gifts and merchandise. This method delivers the detail and quality that make gifts feel special such as a mug with a family photo, a pillowcase with a heartfelt message, or a t-shirt with a unique design.

What’s truly remarkable is the level of customization it supports. You can cater to a wide range of preferences, offering everything from photorealistic designs to bold text graphics. This makes it an excellent choice for businesses focusing on special occasions like weddings, birthdays, or corporate gifts.

Industrial And Corporate Uses (Uniforms, Branding)

Heat transfer printing isn’t just for creative industries, it’s also a practical choice for corporate and industrial applications. Many companies use this method to create uniforms featuring logos, employee names, and branding elements.

Besides, the durability of these prints ensures they withstand rigorous conditions, including frequent washing and exposure to harsh environments.

Beyond uniforms, businesses can also leverage heat transfer printing for branded merchandise like laptop bags, work jackets, or promotional gear. This helps maintain a consistent brand image while offering functional and stylish products that employees and clients appreciate.

Cost to Run Your Heat Transfer Printing

If you’re considering heat transfer printing as your method of choice, understanding the costs involved is crucial since like any business venture, it comes with specific expenses. Let’s break down the key costs so you can make an informed decision about starting or scaling your heat transfer printing operation.

| Cost Category | Details | Estimated Price Range |

|---|---|---|

| Equipment Costs | – Heat press machine: $200-$2,000- Specialty printer: $300-$1,000+ | $500-$3,000 (initial investment) |

| Consumables | – Transfer paper/film: $1-$3 per sheet- Inks: $40-$100 per set | $1-$3 per transfer + $40-$100 (ongoing) |

| Blanks (Items to print) | – Cotton t-shirt: $2-$5- Sublimation mug: $3-$7 | $2-$7 per item |

| Energy Costs | – Heat press usage: 1,200-1,500 watts/hour(~$0.15 per hour) | ~$0.15 per hour of use |

| Maintenance Costs | Cleaning supplies, part replacements | $50-$100 annually |

| Labor Costs (Optional) | Skilled operator for small-medium production runs | Varies based on production scale |

As you can see, running a heat transfer printing setup involves both upfront and ongoing costs. For small to medium-scale operations, an initial investment of $500 to $3,000 can get you started with quality equipment.

After setup, your per-unit cost depends on materials and energy usage, typically ranging from $4 to $10 for items like t-shirts or mugs. Therefore, this method is particularly cost-effective for businesses focusing on small-batch production, personalized orders, or testing new designs.

Common Problems In Heat Transfer Printing

Like any printing technique, heat transfer printing can face challenges. Identifying these issues early and knowing how to resolve them ensures high-quality results and satisfied customers. Below I will give you some common problems and their solutions.

Fading or cracking of the prints

Few things are more frustrating than seeing a once-vivid design fade or crack over time. Often, this issue arises when the heat, pressure, or time settings aren’t quite right during the transfer process.

Additionally, using low-quality materials or improper washing methods, such as tossing items into a hot wash or using harsh detergents, can accelerate wear.

To address this, it’s essential to focus on precision and care. Start by selecting high-quality inks and transfer paper specifically designed for durability. Next, adjust your heat press settings to ensure the design bonds properly to the material.

Finally, don’t forget to share care instructions with your customers such as some simple steps like washing in cold water and air-drying, which can significantly extend the life of their items.

Poor adhesion to the substrate

Another common problem is when a design doesn’t adhere properly to the surface. This issue is often linked to uneven pressure, insufficient heat, or material incompatibility.

For example, fabrics coated with finishes or surfaces that aren’t perfectly clean may resist the transfer process.

To ensure success, preparation is key. Begin by verifying that the material is clean, dry, and suitable for heat transfers. Then, double-check your heat press to confirm the pressure is evenly distributed and the temperature is set correctly.

Plus, if you’re working with a challenging surface, testing a small area first can save time and avoid frustration later.

Uneven or inconsistent transfers

Uneven transfers can leave your design looking patchy, which diminishes the professional appearance of your product. This problem often occurs when the heat press doesn’t apply consistent pressure across the entire design or if the transfer paper isn’t perfectly flat.

To avoid this, start by inspecting your heat press regularly for wear and tear, particularly on the heating plates. Additionally, ensure your transfer paper and material are properly aligned and smooth before pressing.

For extra security, consider using heat-resistant tape to hold the transfer paper in place, which helps prevent shifting during the process and results in an even, flawless finish.

Issues with color accuracy

When working on intricate or custom designs, achieving accurate colors is critical. However, this can sometimes be tricky, especially if the colors printed don’t match what you see on the screen or appear dull after the transfer. This issue is often caused by mismatched printer settings, incompatible inks, or the material’s base color interfering with the design.

To improve color accuracy, it’s important to use ICC profiles that match your printer and inks. Furthermore, if you’re printing on dark fabrics, consider adding a white under base to make colors pop. Finally, running test prints before starting a larger project ensures everything is calibrated perfectly, saving you both time and materials.

Conclusion

Above, I gave you an in-depth look at what is heat transfer printing and its many benefits. From vibrant, long-lasting prints to the flexibility of working with various materials, it’s clear why this method is favored by businesses and creators.

Ready to start? Heat transfer printing will help bring your custom products to the next level!