Are you a business owner who wants to know what DTG printing is and how it might improve your apparel line? This cutting-edge technology is transforming the POD industry by enabling outstanding, full-color graphics to be printed directly onto fabric. In this guide, we’ll delve into the realm of DTG printing so you can see how it benefits your store or advertising efforts.

Contents

What is DTG Printing?

Direct-to-garment (DTG) printing is a digital printing process where designs are printed directly onto fabric using specialized inkjet technology.

Unlike screen printing, which requires stencils, DTG printing allows for detailed, full-color designs to be applied directly to clothing with minimal setup, making it a versatile choice for e-commerce and print-on-demand businesses aiming to produce custom apparel.

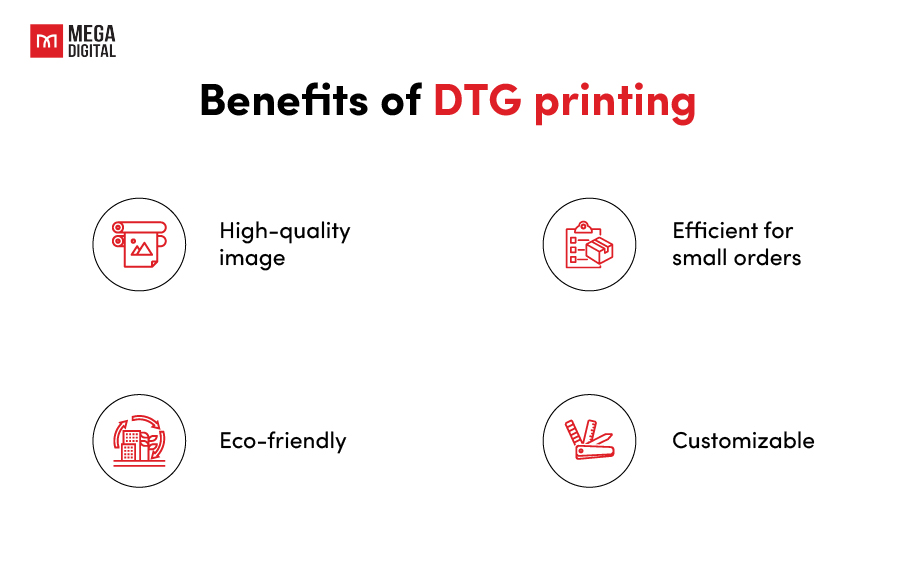

Benefits of DTG Printing

DTG printing offers several key advantages that make it a go-to choice for many businesses looking to produce high-quality apparel. It’s an excellent option for those wanting to deliver vibrant, detailed designs without sacrificing efficiency or sustainability.

- High-quality images: DTG printers can produce photo-realistic images with resolutions up to 1200 DPI, ideal for intricate designs with gradients and multiple colors.

- Efficient for small orders: DTG printing skips the need for screens or plates, reducing costs and allowing quick turnarounds, making it perfect for small or on-demand orders.

- Eco-friendly: DTG uses water-based, non-toxic inks that are biodegradable, and only prints what’s ordered, reducing waste compared to traditional methods.

- Customizable: It’s all about print on demand. Whether customers want a single T-shirt with a personalized message or a collection of custom designs, there’s no extra cost for adding complex artwork or multiple colors, allowing businesses to offer one-of-a-kind products for any occasion.

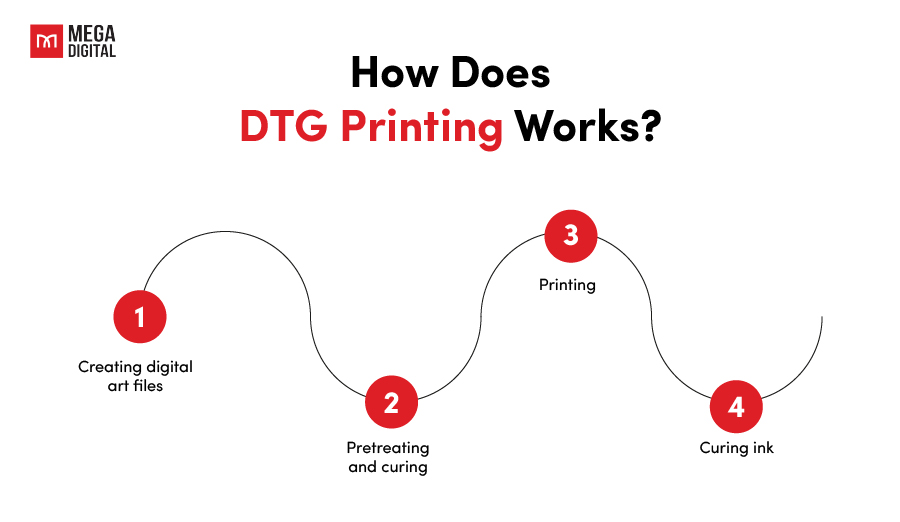

How Does DTG Printing Work?

Now that you know what DTG printing is, let’s explore how the process works to produce those stunning, high-quality prints. Here’s how it unfolds:

- Creating digital art files: Ideally, digital art files should be in formats like PNG or TIFF to maintain color integrity and transparency. This initial step is essential, as the quality of the artwork directly affects the final print.

- Pretreating and curing: After preparing the artwork, a special pretreatment solution is applied to help the ink adhere properly. This treatment ensures that colors remain bright and details are crisp. Following pretreatment, the fabric is cured to set the solution, creating an ideal surface for printing.

- Printing: You need to use advanced inkjet technology, which applies the ink directly to the garment. This method allows for full-color designs to be printed in a single pass, enabling you to achieve intricate details and smooth gradients with ease.

- Curing ink: This process involves heat setting the printed design to ensure it bonds well with the fabric. It not only enhances durability but also makes the design resistant to fading, so your prints will withstand multiple washes without losing their vibrancy.

How Much Does DTG Printing Cost?

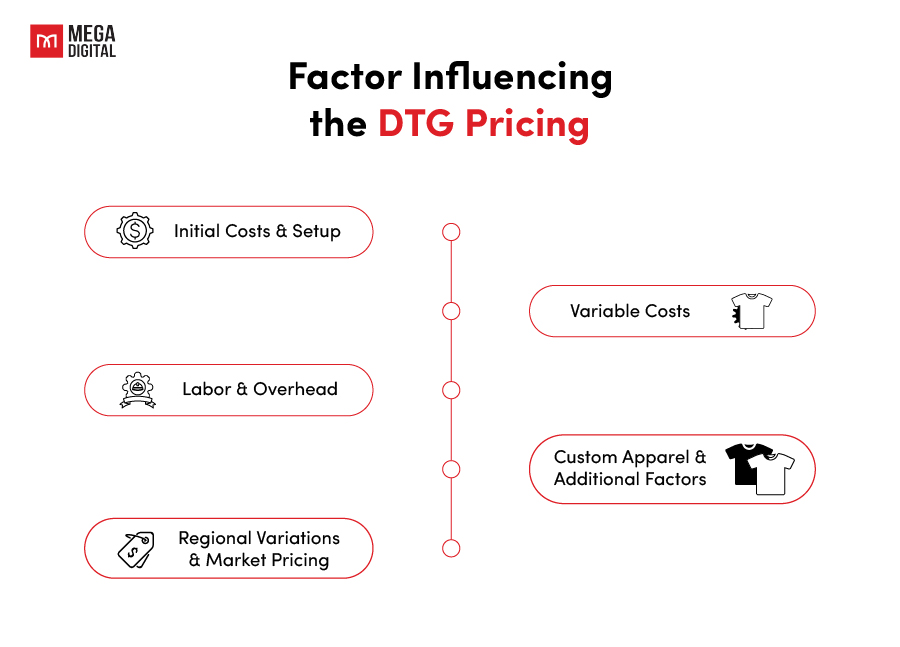

When considering DTG printing, one important factor to evaluate is cost. Understanding the various elements that contribute to the overall expense can help you make informed decisions for your POD business. Let’s break down the key components that influence the cost of DTG printing.

Here are some core costs that you must consider to start your DTG business:

| Item | Price Range |

|---|---|

| DTG Printer | $15,000 – $30,000 |

| Pretreatment Machine | $2,500 – $4,000 |

| Heat Press | $1,000 – $2,000 |

| Ink Costs | $1 – $3 per design |

| Garments | $2 – $20 (Shirts) |

| $3 – $8 (Tote Bags/Hats) | |

| Maintenance and Supplies | $1,000 – $2,000 per year |

| Software and Design Tools | $55 per month |

By factoring in these specific costs, you’re looking at an initial investment of $20,000 to $40,000 to get your DTG printing business up and running. This upfront expense might seem high, but the flexibility and demand for custom apparel can make it a lucrative long-term venture.

Note: Besides the fundamental costs, advertising and marketing costs are other factors that are worth considering to boost your visibility and sales. You can expect to allocate $500 to $5,000 monthly for advertising and marketing costs, covering platform ads, content creation, social media promotions, and influencer collaborations.

>>> Read more: Top 7 Best Dropshipping Niches to Scale Your Business in 2024

Types of DTG Printers

When choosing a DTG printer for your business, it’s important to understand the different types available since each category serves specific needs. Here’s a quick overview of the main types of DTG printers on the POD market:

Entry-Level-Compact DTG Printers

These printers are ideal for small businesses or startups. They’re compact, user-friendly, and designed for low to medium-volume printing.

While they have slower print speeds and fewer features compared to larger models, they’re perfect for businesses offering custom, one-off products or handling smaller orders. Prices for entry-level printers typically range from $10,000 to $15,000.

Commercial DTG Printers

Built for businesses looking to scale up, commercial DTG printers offer faster print speeds and higher output capabilities. These machines are suitable for handling larger orders and printing on a variety of garments like hoodies, hats, or tote bags.

Commercial printers are more durable and provide better color consistency, making them a great choice for growing businesses. You may expect to pay between $20,000 and $30,000 for a quality commercial DTG printer.

>>> Read more: What Is Sublimation Printing in POD? A Comprehensive Guide

Industrial DTG Printers

For large-scale operations, industrial DTG printers are the top choice. These machines are designed to handle high-volume production with exceptional speed and precision. They can print hundreds of items per day and are ideal for businesses focused on mass production, like major apparel brands or large print-on-demand services.

Industrial models offer advanced features like automated pretreatment and higher ink efficiency, but they come with a hefty price tag, usually ranging from $50,000 to $100,000 or more.

Tips to Get Started with DTG Printing

Getting started with DTG printing requires careful planning and a solid understanding of both the equipment and processes involved. Each decision can significantly affect your success, so let’s dive into some key tips to help you thrive in the POD industry.

Invest in the Right Equipment

The equipment you choose will directly affect your production capacity and quality. If you’re starting small, an entry-level printer might be enough, but keep in mind that these machines can limit your output.

If you plan to boost sales and grow your business, investing in a commercial or industrial-grade printer might be a smarter long-term decision.

For instance, while an entry-level model may handle 10-20 garments per hour, a commercial-grade machine can handle 50 or more. The extra speed and capabilities of higher-end printers allow you to take on more orders, boost revenue, and stay competitive as your business expands.

Understand Your Design Software

Design software is the backbone of your DTG business and programs like Adobe Photoshop, Illustrator, and CorelDRAW are the industry standards.

For example, vector-based designs are essential for resizing without losing image quality, which is particularly important when working on different garment sizes or when scaling up a design for a large print area.

It’s also important to understand how to optimize your files for DTG printing. For instance, using high-resolution images (typically 300 DPI) ensures that your prints come out sharp and vibrant.

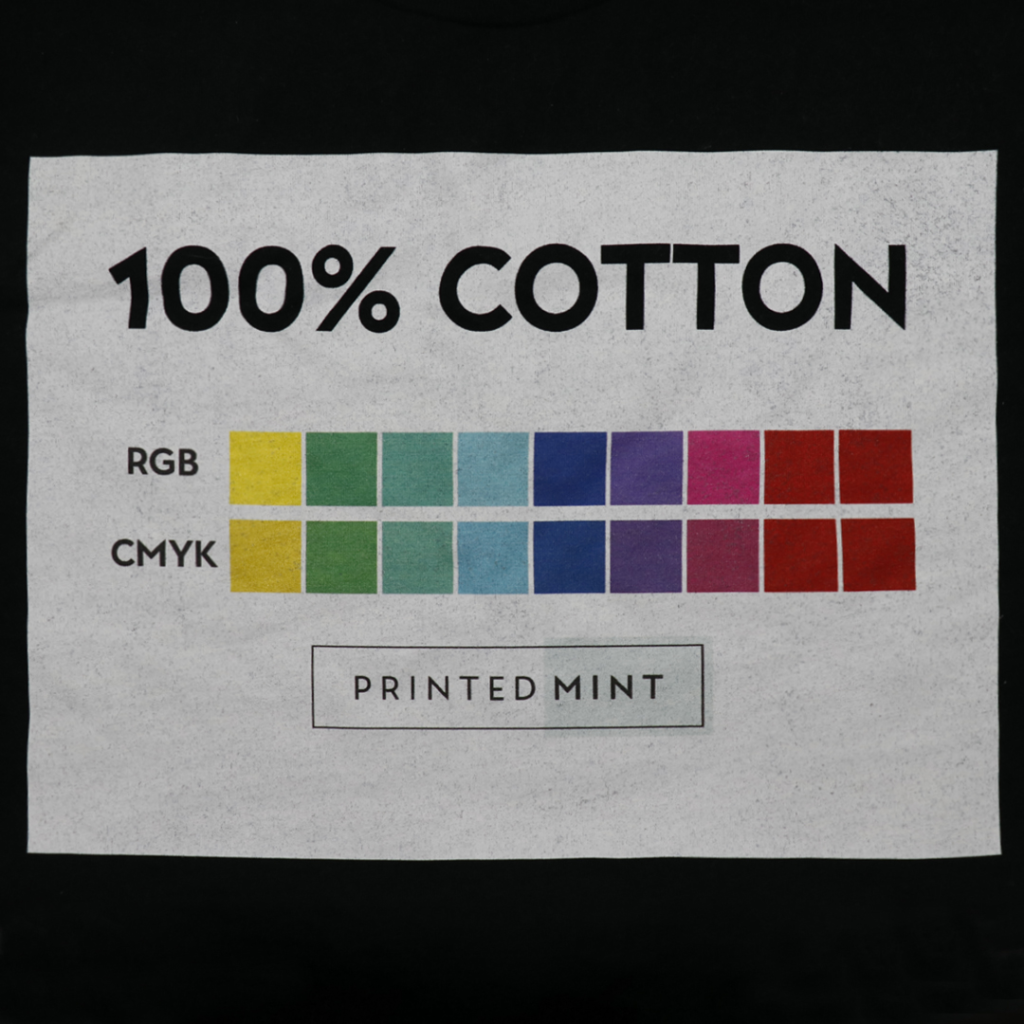

Additionally, learning about color profiles like CMYK vs. RGB can help avoid color discrepancies when the design moves from screen to fabric. Therefore, taking the time to master these programs will save you from costly mistakes and ensure professional results every time.

Try Different Colors and Textures

One of the key advantages of DTG printing is its versatility. You’re not limited to just white cotton T-shirts since DTG works on a range of materials and colors. By experimenting with different textures and materials, you can offer a wider range of products, such as hoodies, bags, or aprons, making your business more appealing to diverse customers.

However, printing on darker fabrics requires proper pretreatment to get the best results. If you’re planning to print on hoodies, tote bags, or other textured materials like polyester blends, it’s essential to run tests first.

Dark fabrics, for example, absorb ink differently, which could result in dull colors if not pretreated properly. You can experiment with vibrant designs on dark-colored fabrics. Pretreating your garments correctly can make the colors pop, leading to eye-catching, premium products that customers love.

Test Your Prints

Testing is essential for ensuring quality before you commit to larger runs. Even if your design looks perfect on screen, it might not print as expected.

Some DTG business owners use test prints to fine-tune their ink settings, ensuring that every design looks just as good on fabric as it does on a computer screen. Consistent testing will not only save you from costly errors but also keep your customers satisfied with the final product.

For example, if you’re printing on a textured fabric like a hoodie, running a sample print helps you catch issues like color distortion or uneven ink application.

Maintain Your Equipment

Keeping your equipment in good condition is non-negotiable if you want consistent, high-quality prints. Regular cleaning of your printer’s print heads, for instance, ensures the ink flows smoothly and prevents clogs. This is especially important if you print frequently or use heavy ink applications.

Neglecting maintenance can lead to clogged nozzles or streaky prints, which can halt production. You can schedule maintenance checks, such as replacing worn-out parts, running cleaning cycles, and inspecting pretreatment machines to prevent downtime and costly repairs.

Some business owners schedule monthly or quarterly checkups to ensure their equipment stays in peak condition. Regular maintenance not only prolongs the life of your machine but also guarantees consistent, high-quality prints, which are key to customer retention.

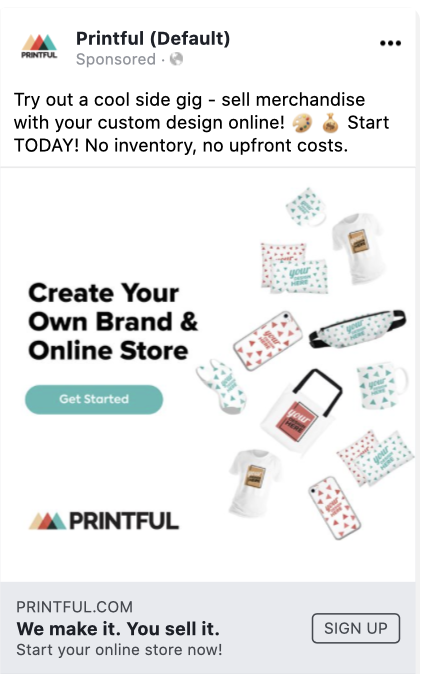

Experiment with Marketing

Marketing is just as essential as printing quality products. One powerful strategy is Pay-Per-Click (PPC) advertising on platforms like Google Ads and Facebook Ads.

For instance, Printful, a well-known print-on-demand company, used targeted Facebook ads to promote their custom apparel. By focusing on specific demographics, such as young adults interested in fashion and art, they saw a significant increase in sales, reporting over 300% growth in their first year of PPC campaigns.

Ready to boost your visibility and grow your DTG business through effective PPC strategies? Connect with Mega Digital today so we can help you optimize your campaigns for maximum impact.

Plus, social media platforms like Instagram and TikTok can also be powerful tools for promoting your designs.

Merch by Amazon is another notable example; they use Instagram to run a campaign featuring user-generated content where customers post photos of themselves wearing seasonal products. This approach led to a 40% increase in engagement and boosted their sales, showcasing the power of authentic customer stories in driving brand awareness.

Recommended Textiles for DTG Printing (with Product Examples)

When it comes to DTG printing, the choice of textiles plays a crucial role in determining print quality and overall satisfaction. In this part, I will give you recommended fabrics that deliver exceptional results, along with examples that illustrate their effectiveness.

Cotton

Cotton is the gold standard for DTG printing. One of the primary benefits of cotton is its ability to produce vibrant colors and sharp images, which makes it ideal for a variety of designs.

For example, the Gildan 2000 Heavy Cotton T-Shirt typically costs between $3 and $5. This affordability, coupled with its reliability in print quality, makes it a staple choice for many businesses. Furthermore, cotton’s breathability ensures comfort, which can lead to higher customer satisfaction and repeat purchases.

Ring-spun Cotton

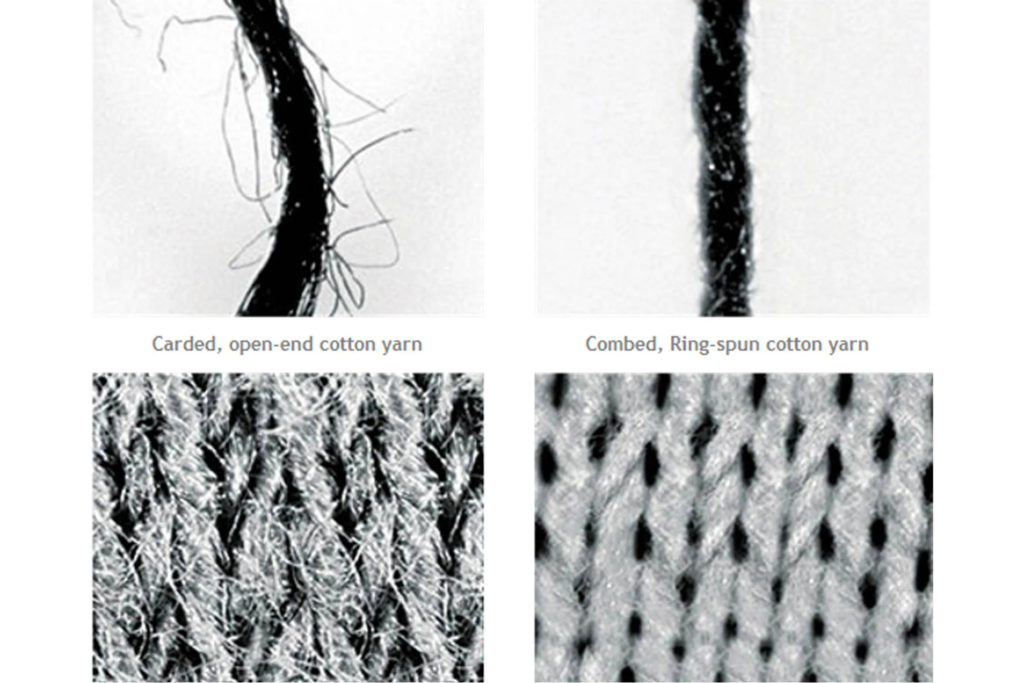

For a softer finish, ring-spun cotton is a superior choice. This fabric is a step up in softness and durability. Through a special spinning process, ring-spun cotton creates a smoother texture that enhances the overall feel of the garment.

As a result, brands using ring-spun cotton often report higher customer retention and increased sales, especially for trendy or fashion-forward designs.

A great example is the Bella+Canvas 3001 Unisex Short Sleeve Tee, which is priced around $7 to $10. This shirt not only looks great but feels luxurious against the skin.

Combed and Ring-spun Cotton

For those seeking the ultimate in comfort and quality, combed and ring-spun cotton is highly recommended. This fabric is meticulously treated to remove short fibers and impurities, resulting in a remarkably smooth surface that enhances print quality.

For these textiles, the Next Level 3600 Premium Fitted Short Sleeve T-Shirt is an excellent choice, retailing for about $8 to $12. Despite the higher price point, many businesses find that customers are willing to pay a premium for this luxurious feel, leading to increased customer loyalty and higher profit margins.

Organic Cotton

With sustainability on the rise, organic cotton has become an appealing option for eco-conscious brands. This fabric is grown without harmful pesticides and chemical fertilizers, making it an environmentally friendly choice.

The Royal Apparel Organic Cotton T-Shirt, priced between $10 and $15, not only supports sustainable practices but also meets the demand for high-quality apparel. By marketing these shirts, you can tap into a growing market of environmentally aware consumers to foster brand loyalty and attract new environment enthusiast customers.

Linen and Other Natural Textiles

While cotton is a top choice, linen and other natural textiles offer unique aesthetics and textures that can set your products apart. Linen is lightweight and breathable, making it perfect for summer styles, although it may require more careful handling during printing due to its texture.

For instance, linen-blend shirts from American Apparel provide a stylish option for those looking to stand out. Although these products might need some experimentation to achieve optimal print quality, they can attract a niche market seeking distinctive and trendy apparel.

DTG vs. Screen Printing: Which One to Choose?

People always consider the differences between DTG printing and screen printing when deciding how to produce their apparel. Each method has its strengths, making the choice dependent on specific needs. Now I will give you a quick comparison that highlights the key features of both printing techniques:

| Feature | DTG Printing | Screen Printing |

|---|---|---|

| Quality | Offers exceptional photorealistic prints. | Produces vibrant, high-quality images. |

| Durability | Can endure over 50 washes without fading. | Known for long-lasting prints on garments. |

| Design Complexity | Ideal for intricate and detailed designs. | Better suited for simpler designs. |

| Sustainability | Utilizes water-based inks and is energy-efficient. | Generally uses more water, leading to potential overproduction. |

| Minimum Order | Allows for printing as few as one item. | Typically requires a minimum of 5 to 100 units. |

| Production Time | Generally slower, best for small orders. | Faster for larger orders after setup. |

| Cost | Economical for small quantities but less so for bulk. | More costly for small runs but cost-effective for larger quantities. |

In choosing between DTG printing and screen printing, consider your specific needs: DTG is ideal for high-quality, intricate designs in small quantities, making it perfect for custom apparel, while screen printing is more cost-effective for bulk orders and simpler designs, ensuring durability.

Conclusion

Above, I gave you a comprehensive look at what DTG printing is and how it can benefit your custom apparel business. With its vibrant print quality, eco-friendly processes, and versatility, DTG printing is an excellent choice for meeting diverse customer needs.

I hope through my guidance, you could embrace this technology to enhance your brand and attract more customers!